Ford Fusion: Front End Sheet Metal Repairs / Front Side Member Section. Removal and Installation

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| Air Body Saw | |

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

NOTE: The required partial replacement sections need to be cut out from the outer side member with apron panel or from the inner side member.

-

Follow the health and safety precautions. WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation).

-

Remove the following items.

Refer to: Fender Apron Panel Reinforcement (501-27 Front End Sheet Metal Repairs, Removal and Installation).

Refer to: Front Bumper (501-19 Bumpers, Removal and Installation).

Refer to: Engine (303-01C Engine - 2.5L Duratec (125kW/170PS), Removal).

Refer to: Radiator (303-03B Engine Cooling - 2.0L EcoBoost (184kW/250PS) – MI4, Removal and Installation).

Refer to: Radiator (303-03C Engine Cooling - 2.5L Duratec (125kW/170PS), Removal and Installation).

NOTICE: Due to the positions of inner reinforcements and laser weld seams it is important to follow indicated dimensions of cut points.

-

NOTE: Sectioning cut locations apply to right hand (RH) and left hand (LH) side.

NOTE: Overview of possible sectioning locations. Do not cut within 40 mm of laser welded seam.

-

Long section measurement.

-

Short section measurement.

-

Laser welded seam.

-

Long section measurement.

|

-

Carefully cut the front side member frame rail.

Use the General Equipment: Air Body Saw

|

-

Drill out the spot welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

Drill out the spot welds and remove the front side member section.

Use the General Equipment: Spot Weld Drill Bit

|

Installation

WARNING:

Before beginning any service procedure in this section,

refer to Safety Warnings in section 100-00 General Information. Failure

to follow this instruction may result in serious personal injury.

WARNING:

Before beginning any service procedure in this section,

refer to Safety Warnings in section 100-00 General Information. Failure

to follow this instruction may result in serious personal injury.

NOTE: The required partial replacement section needs to cut out from the service replacement part.

-

Cut replacement assembly to fit repair.

Use the General Equipment: Air Body Saw

|

-

NOTE: Indicated holes will be used for puddle welding.

-

Install the spot welds.

Use the General Equipment: 8 mm Drill Bit

-

Install the spot welds.

|

-

Install and properly position the component and install spot welds.

Use the General Equipment: Resistance Spotwelding Equipment

Use the General Equipment: Locking Pliers

|

-

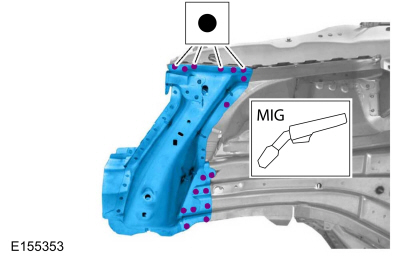

Seam weld as indicated.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Install spot welds.

Use the General Equipment: Resistance Spotwelding Equipment

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Install the bumper bracket and spot weld.

Use the General Equipment: Resistance Spotwelding Equipment

|

-

Finish the repair area using typical metal finishing procedures.

-

Sealing work: All areas must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Install the following items.

Refer to: Fender Apron Panel Reinforcement (501-27 Front End Sheet Metal Repairs, Removal and Installation).

Refer to: Front Bumper (501-19 Bumpers, Removal and Installation).

Refer to: Engine (303-01C Engine - 2.5L Duratec (125kW/170PS), Installation).

Refer to: Radiator (303-03B Engine Cooling - 2.0L EcoBoost (184kW/250PS) – MI4, Removal and Installation).

Refer to: Radiator (303-03C Engine Cooling - 2.5L Duratec (125kW/170PS), Removal and Installation).

Dash Panel Reinforcement. Removal and Installation

Dash Panel Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Removal

NOTICE:

Battery electric vehicle (BEV), hybrid electric vehicle

(HEV) and plug-in hybrid electric vehicle (PHEV) contain a high-voltage

battery...

Fender Apron Panel Reinforcement. Removal and Installation

Fender Apron Panel Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Spherical Cutter

Grinder

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

WARNING:

Before beginning any service procedure in this

se..

Other information:

Ford Fusion 2013–2020 Owners Manual: Pre-Collision Assist (IF EQUIPPED)

WARNING: You are responsible for controlling your vehicle at all times. The system is designed to be an aid and does not relieve you of your responsibility to drive with due care and attention. Failure to follow this instruction could result in the loss of control of your vehicle, personal injury or death. WARNING: The system does not detect vehicles that are driving in a different direct..

Ford Fusion 2013–2020 Service Manual: Front Floor Panel Upper Rear Crossmember. Removal and Installation

Special Tool(s) / General Equipment 8 mm Drill Bit MIG/MAG Welding Equipment Spot Weld Drill Bit Locking Pliers Materials Name Specification Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM - Removal NOTICE: Battery electric vehicle (BEV), hybrid electric vehicle (HEV) and plug-in hybrid electric vehicle (PHEV) contain a high-voltage battery..

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Transmission - 1.5L EcoBoost (118kW/160PS) – I4. Removal and Installation

- Traction Control

- Load Carrying

- New on site

- Most important about car

Understanding Your Tire Pressure Monitoring System

The tire pressure monitoring system measures pressure in your road tires and sends the tire pressure readings to your vehicle. You can view the tire pressure readings through the information display. The low tire pressure warning light will turn on if the tire pressure is significantly low. Once the light is illuminated, your tires are under-inflated and need to be inflated to the manufacturer’s recommended tire pressure. Even if the light turns on and a short time later turns off, your tire pressure still needs to be checked.