Ford Fusion: Intake Air Distribution and Filtering - 1.5L EcoBoost (118kW/160PS) – I4 / Charge Air Cooler (CAC) Coolant Pump. Removal and Installation

Ford Fusion 2013–2020 Service Manual / Powertrain / Engine / Intake Air Distribution and Filtering - 1.5L EcoBoost (118kW/160PS) – I4 / Charge Air Cooler (CAC) Coolant Pump. Removal and Installation

Special Tool(s) / General Equipment

| Hose Clamp(s) | |

| Hose Clamp Remover/Installer |

Materials

| Name | Specification |

|---|---|

| Motorcraft® Orange Prediluted Antifreeze/Coolant VC-3DIL-B |

WSS-M97B44-D2 |

Removal

NOTE: Removal steps in this procedure may contain installation details.

-

With the vehicle in N, position it on a hoist.

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

-

NOTE: When releasing the cooling system pressure, cover the coolant expansion tank cap with a thick cloth.

Loosen: 2 turn(s)

-

Tighten the cap.

Torque: 2 turn(s)

|

-

Remove the retainers and the engine undershield.

|

-

-

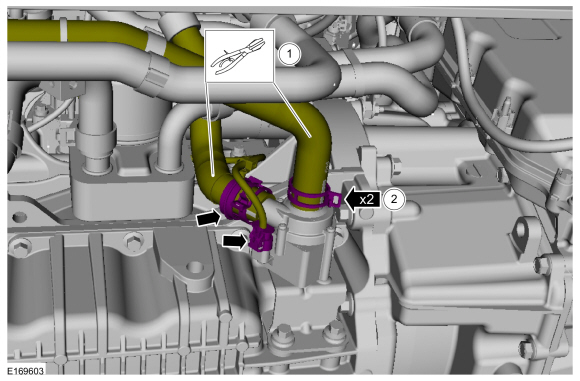

Clamp off the coolant hoses.

Use the General Equipment: Hose Clamp(s)

-

Detach the clip, disconnect the electrical connector and the coolant hoses.

Use the General Equipment: Hose Clamp Remover/Installer

-

Clamp off the coolant hoses.

|

-

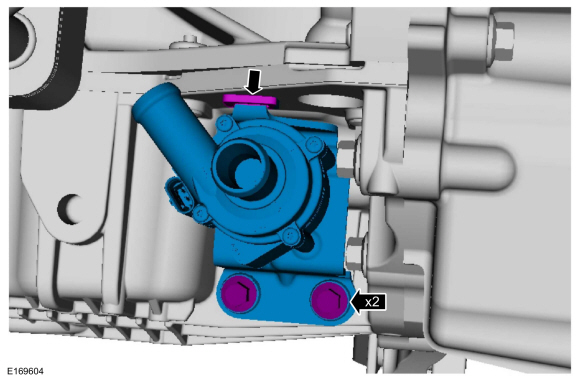

Remove the bolts, release the tab and remove the CAC coolant pump.

Torque: 97 lb.in (11 Nm)

|

Installation

-

To install, reverse the removal procedure.

-

Check the coolant level in the degas bottle and add coolant as necessary.

Material: Motorcraft® Orange Prediluted Antifreeze/Coolant / VC-3DIL-B (WSS-M97B44-D2)

|

Air Cleaner Outlet Pipe. Removal and Installation

Air Cleaner Outlet Pipe. Removal and Installation

Special Tool(s) /

General Equipment

Hose Clamp Remover/Installer

Removal

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles...

Charge Air Cooler (CAC) Intake Pipe. Removal and Installation

Charge Air Cooler (CAC) Intake Pipe. Removal and Installation

Special Tool(s) /

General Equipment

Hose Clamp Remover/Installer

Removal

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles...

Other information:

Ford Fusion 2013–2020 Service Manual: Transmission Case. Disassembly and Assembly of Subassemblies

Special Tool(s) / General Equipment 205-153 (T80T-4000-W) Handle 206-084Installer, Wheel Speed Sensor RingTKIT-2003-FLM/LMTKIT-2003D-F 307-664Case Bushing InstallerTKIT-2009OP-FLMTKIT-2009OP-ROW Flat Headed Screw Driver Hydraulic Press Materials Name Specification Loctite® 6481835922 WSK-M2G349-A4 DISASSEMBLY NOTE: The transm..

Ford Fusion 2013–2020 Owners Manual: Driver Alert

Principle of Operation WARNING: You are responsible for controlling your vehicle at all times. The system is designed to be an aid and does not relieve you of your responsibility to drive with due care and attention. Failure to follow this instruction could result in the loss of control of your vehicle, personal injury or death. WARNING: The system may not function if the sensor is blocked..

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Intake Manifold. Removal and Installation

- Garage Door Opener

- Load Carrying

- New on site

- Most important about car

Direction Indicators. Interior Lamps

Direction Indicators

Push the lever up or down to use the direction indicators.

Copyright © 2025 www.fofusion2.com