Ford Fusion: Automatic Transmission - 6-Speed Automatic Transmission – 6F35 / Transmission. Overhaul

Special Tool(s) / General Equipment

|

100-001

(T50T-100-A)

Slide Hammer |

|

100-002

(TOOL-4201-C)

Holding Fixture with Dial Indicator Gauge |

|

205-153

(T80T-4000-W)

Handle |

|

211-061

(T78P-3504-N1)

Remover, Roll Pin |

|

303-D011

(D80L-100-G)

Actuator Pin (Dia 3/16) |

|

303-D019

(D80L-100-Q)

Collet, 3/4 to 7/8 |

|

307-003

(T57L-500-B)

Holding Fixture, Transmission |

|

307-091 Handle, Torque Converter TKIT-2009TC-F |

|

307-300 Gauge Bar, Shim Selection TKIT-1994-LMH/MH2 TKIT-1994-F TKIT-1994-FLM/FM |

|

307-566 Retainer, Torque Converter TKIT-2006C-FFMFLM TKIT-2006C-LM TKIT-2006C-ROW |

|

307-574 Forward Clutch Spring Compressor TKIT-2006UF-FLM TKIT-2006UF-ROW |

|

307-578 Input Shaft Support Seal Installer (Back Plate, Multiple rings) TKIT-2006UF-FLM TKIT-2006UF-ROW |

|

307-581 Manual lever seal installer TKIT-2006UF-FLM TKIT-2006UF-ROW |

|

307-584 2-6 Spring Compressor TKIT-2006UF-FLM TKIT-2006UF-ROW |

|

307-589 Overdrive clutch and balance piston service set TKIT-2006UF-FLM TKIT-2006UF-ROW |

|

307-625 Fixture, Bench Mounting TKIT-2008ET-FLM TKIT-2008ET-ROW |

|

307-626 Installer, Differential Seal TKIT-2008ET-FLM TKIT-2008ET-ROW |

|

307-627 Installer, Converter Seal TKIT-2008ET-FLM TKIT-2008ET-ROW |

|

307-628 Protector, Low Reverse Piston Seal TKIT-2008ET-FLM TKIT-2008ET-ROW |

|

307-629 Protector, Low Reverse / 1-2-3-4 Piston Seal TKIT-2008ET-FLM TKIT-2008ET-ROW |

|

307-630 Center Support Piston Spring Tool TKIT-2008ET-FLM TKIT-2008ET-ROW |

|

307-632 Protector, 2-6 Piston Seal TKIT-2008ET-FLM TKIT-2008ET-ROW |

|

307-633 2-6 Piston return spring Comp TKIT-2008ET-FLM TKIT-2008ET-ROW |

|

307-635 Protector, Turbine Shaft Seal TKIT-2008ET-FLM TKIT-2008ET-ROW |

|

307-691 Tester, Torque Convertor Leak |

|

307-718 Installer, Axle Seal TKIT-2013B-FL TKIT-2013B-ROW |

|

307-723 Installer, Turbine Seal TKIT-2014A-FL |

|

307-732 Tool Kit, Torque Converter Flusher |

| Flat Headed Screw Driver | |

| Magnetic Socket | |

| Hydraulic Press | |

| Long Nose Pliers | |

| Puller | |

| Punch | |

Materials

| Name | Specification |

|---|---|

| Motorcraft® Ultra Silicone Sealant TA-29 |

WSS-M4G323-A8 |

| Motorcraft® MERCON® LV Automatic Transmission Fluid XT-10-QLVC |

WSS-M2C938-A MERCON® LV, |

All vehicles

-

For information on component views and base part numbers.

Refer to: Transmission Description (307-01A Automatic Transmission - 6-Speed Automatic Transmission – 6F35, Description and Operation).

-

NOTE: Use M10 x 1.5 x 25mm bolts to attach the special tool to the transmission case.

Install the special tool.

Use Special Service Tool: 307-732 Tool Kit, Torque Converter Flusher. , 307-625 Fixture, Bench Mounting.

|

-

Mount the transmission to the bench-mounted holding fixture.

Use Special Service Tool: 307-003 (T57L-500-B) Holding Fixture, Transmission. , 307-625 Fixture, Bench Mounting.

|

-

Remove the special tool.

Use Special Service Tool: 307-566 Retainer, Torque Converter.

|

-

NOTICE: The torque converter is heavy. Be careful not to drop it or damage will result.

Using the special tools, remove the torque converter from the transmission.

Use Special Service Tool: 307-091 Handle, Torque Converter.

|

-

A new or remanufactured torque converter must be installed if one or more of the following statements are true:

-

The sealing surface has a groove worn from the seal.

-

A torque converter malfunction has been determined based on complete diagnostic procedures.

-

The torque converter stud or studs, threaded pads, impeller hub or bushing are damaged.

-

The torque converter exhibits external discoloration (due to overheating).

-

There is evidence of water or antifreeze contamination.

-

The sealing surface has a groove worn from the seal.

|

Flush The Torque Converter With The Transmission Cooling System Heated Flusher

-

NOTE: Use transmission fluid specified for this transmission. Do not use any supplemental transmission fluid additives or cleaning agents. The use of these products could cause internal transmission components to fail, which will affect the operation of the transmission.

The torque converter must be flushed every time the transmission is overhauled. It is mandatory that proper equipment and procedures be followed when flushing the torque converter. The flushing equipment used MUST:

-

Maintain the transmission fluid at 140°F or above

-

Pulsate the transmission fluid during cleaning

-

Have a GPM flow meter

-

Have a filter with a rating of 100 micron or less

-

Have air purge capability before and after flushing

-

Maintain the transmission fluid at 140°F or above

-

If equipment meeting the specifications above is not

available, the torque converter must be flushed by hand. Go to Flush The

Torque Converter By Hand steps later in this procedure.

-

Check and top off the transmission fluid level of the

transmission cooling system heated flusher with transmission fluid.

-

Turn on the heater and allow the transmission fluid in

the transmission cooling system heated flusher 15-30 minutes to heat up

to 60°C (140°F) before using.

-

Place the torque converter in an arbor press. Support the torque converter on the mounting pads.

|

-

Using the special tools, assemble the correct turbine

shaft simulator to the torque converter flush main hub and place it on

the torque converter hub.

Use Special Service Tool: 307-732 Tool Kit, Torque Converter Flusher.

|

-

Using the special tool, install the slotted cap.

Use Special Service Tool: 307-691 Tester, Torque Convertor Leak.

|

-

Apply enough force from the press to seal the torque converter flush main hub to the torque converter hub.

|

-

Connect the flush machine to the main hub.

-

Red hose on top.

-

Blue hose on bottom.

-

Red hose on top.

|

-

Follow the equipment instructions to purge transmission

fluid from the torque converter prior to starting the flushing

procedure.

-

WARNING:

The torque converter, adaptor 307-732, and the hoses will be hot.

WARNING:

The torque converter, adaptor 307-732, and the hoses will be hot.

NOTE: Maintain visual contact with torque converter during the entire flush procedure. Immediately stop the flush machine if a leak develops. Repeat set up steps to reseal the tool to the converter hub and continue flushing.

Forward flush the converter for 15 minutes.

-

Monitor GPM flow meter periodically during the flush

procedure. Flow rate above 2.0 gallons per minute is required to break

up and dislodge any contamination trapped behind the TCC plate. Service flush machine filter(s) if flow rate drops below 2 GPM.

-

Follow the equipment instructions to purge the torque converter.

-

Allow torque converter and equipment to cool for 30 minutes before handling. WARNING:

The torque converter, adaptor 307-732, and the hoses will be hot.

WARNING:

The torque converter, adaptor 307-732, and the hoses will be hot.

-

Disconnect the hoses and remove the special tools.

Flush The Torque Converter By Hand

NOTICE: Do not use water-based cleaners or mineral spirits to clean or flush the torque converter or transmission damage will occur. Use only clean transmission fluid designated for the transmission and torque converter being serviced.

NOTE: Only flush the torque converter by hand when the transmission cooling system heated flusher is not available.

-

Pour a small amount of transmission fluid from the

torque converter onto an absorbent white tissue or through a paper

filter.

-

Examine the transmission fluid for contaminants. The

transmission fluid must be free of metallic contaminants. If metallic

contaminants are present, do not continue with hand flushing. The torque

converter must be flushed with the transmission cooling system heated

flusher.

-

Drain the remaining transmission fluid from the torque converter.

-

Using only the recommended transmission fluid, add 1.9L

(2 qt) of clean transmission fluid into the converter and agitate by

hand.

Material: Motorcraft® MERCON® LV Automatic Transmission Fluid / XT-10-QLVC (WSS-M2C938-A) (MERCON® LV, )

|

-

Thoroughly drain the transmission fluid.

Auto-Start-Stop

NOTE: On some vehicles the transmission fluid auxiliary pump is removed during the transmission removal.

-

NOTICE: Do not use power tools to remove the transmission fluid auxiliary pump bolts or damage can occur.

Remove the bolts and the transmission fluid auxiliary pump.

-

Apply heat to the bolts to soften the Loctite®.

-

Remove and discard the bolts.

-

Apply heat to the bolts to soften the Loctite®.

|

-

Remove the transmission fluid auxiliary pump gasket.

|

-

Remove the transmission fluid auxiliary pump supply tube assembly.

|

All vehicles

-

NOTE: Note the location of the stud bolts for assembly.

Remove the main control cover bolts and the main control cover.

|

-

Disconnect the OSS sensor electrical connector.

|

-

Disconnect the TR sensor electrical connector.

|

-

Remove the main control-to-cover seal.

|

-

NOTICE: If the transmission internal wiring harness frame has melted due to overheat condition the transmission and cooler must be replaced.

NOTE: Note the location of the short and long main control-to-transmission case bolts for reassembly.

Remove the main control nut and the main control-to-transmission case bolts and remove the main control assembly.

|

-

Inspect the main control assembly for damage. If damage

is found install a new main control assembly. If the main control

assembly is not damaged, disassemble the main control assembly and clean

it.

Refer to: Main Control Valve Body (307-01A Automatic Transmission - 6-Speed Automatic Transmission – 6F35, Overhaul).

|

-

Remove and discard the main control-to-transmission case separator plate.

|

-

Remove and discard the forward (1, 2, 3, 4) clutch and

low/reverse clutch main control-to-transmission case seals.

|

-

Remove the TSS sensor bolt and the TSS sensor.

|

-

Remove the TR sensor detent spring bolt and the TR sensor detent spring.

|

-

Remove the OSS sensor bolt and the OSS sensor.

|

-

NOTE: Note the location of the stud bolts for assembly.

Remove the torque converter housing bolts.

|

-

Pry the torque converter housing loose from the transmission case.

|

-

Remove the torque converter housing from the transmission case.

|

-

Remove the No. 15 differential thrust bearing.

|

-

Remove the differential assembly.

|

-

Check that the bearings spin freely and do not move back

and forth or side to side excessively. Check for damage or excessive

wear. Install a new differential, if necessary.

|

-

Remove the differential sun gear.

|

-

Inspect the differential sun gear for damage or wear and install new, as necessary.

|

-

NOTE: If the transmission plastic baffle has melted due to overheat condition the transmission and cooler must be replaced.

Remove the differential transmission fluid baffle.

|

-

-

Remove the No. 13 thrust washer.

-

Remove the No. 11 drive sprocket thrust bearing.

-

Remove the No. 13 thrust washer.

|

-

Simultaneously remove the drive and driven sprockets and the chain.

|

-

Remove the drive chain from the drive and driven sprockets.

|

-

Clean and inspect the drive chain for damage or excessive wear and install new, if necessary.

-

Check for stretching or tightness of the chain links.

-

Check that the chain moves freely.

-

Check for stretching or tightness of the chain links.

|

-

Inspect the driven sprocket for damage or excessive wear and install new, if necessary.

-

Chain teeth

-

Spline teeth

-

Thrust bearing surfaces

-

Bearing

-

Chain teeth

|

-

Remove the snap ring and remove the drive sprocket from the front planetary hub/park gear assembly.

|

-

Inspect the drive sprocket for damage or excessive wear and install new, if necessary.

-

Chain teeth

-

Spline teeth

-

Thrust washer surface

-

Chain teeth

|

-

Inspect the front planetary hub/park gear assembly for damage or excessive wear and install new, if necessary.

-

Park gear teeth

-

Spline teeth

-

Thrust washer surface

-

Thrust bearing surface

-

Bearing surfaces

-

Needle bearing

-

Park gear teeth

|

-

Install the drive sprocket on the front planetary hub/park gear assembly and install the snap ring.

|

-

Install the drive chain on the drive and driven sprockets.

|

-

-

Remove the No. 12 driven sprocket thrust bearing.

-

Remove the No. 10 front sun gear and shell assembly thrust bearing.

-

Remove the No. 12 driven sprocket thrust bearing.

|

-

Remove the fluid reservoir bolts and the fluid reservoir.

|

-

Remove the transmission fluid baffle bolts and the transmission fluid baffle.

|

-

Remove the park pawl pin and spring.

|

-

Remove the park pawl.

|

-

NOTE: The forward (1, 2, 3, 4) clutch snap ring is beveled. The beveled side of the snap ring goes up (flat side down).

NOTE: The forward (1, 2, 3, 4) clutch snap ring gap faces the front of the transmission.

Remove the forward (1, 2, 3, 4) clutch snap ring.

|

-

Remove the forward (1, 2, 3, 4) clutch pressure plate, clutch assembly and wave spring.

|

-

Inspect the clutch plate and pressure plate surfaces for damage or excessive wear.

|

-

Remove the front planetary sun gear and shell assembly.

|

-

Clean and inspect the front planetary sun gear and shell assembly for damage or wear and install new, as necessary.

-

Gear teeth

-

Shell-to-clutch pack surfaces

-

Thrust bearing surfaces

-

Gear teeth

|

-

Remove the front planetary carrier/rear ring gear assembly.

|

-

Clean and inspect the front planetary carrier/rear ring gear assembly for damage or excessive wear and install new, as necessary.

-

Pinion gear teeth

-

Pinion gear surfaces

-

Pinion gear bearings

-

Spline teeth

-

Thrust bearing

-

Thrust bearing surfaces

-

Ring gear teeth

-

Pinion gear teeth

|

-

-

Remove the No. 7 thrust bearing.

-

Remove the No. 8 thrust bearing.

-

Remove the No. 7 thrust bearing.

|

-

Remove the center planetary carrier/front ring gear assembly.

|

-

Clean and inspect the center planetary carrier/front ring gear assembly for damage or excessive wear and install new, as necessary.

-

Pinion gear teeth

-

Pinion gear surfaces

-

Pinion gear bearings

-

Spline teeth

-

Thrust bearing surfaces

-

Ring gear teeth

-

Pinion gear teeth

|

-

Remove the center planetary sun gear.

|

-

Clean and inspect the center planetary sun gear for damage or excessive wear and install new, as necessary.

-

Sun gear teeth

-

Spline teeth

-

Sun gear teeth

|

-

-

Remove the No. 5 thrust bearing.

-

Remove the No. 6 thrust bearing.

-

Remove the No. 5 thrust bearing.

|

-

Remove the center support assembly.

|

-

Remove the rear planetary carrier/center ring gear assembly.

|

-

Clean and inspect the rear planetary carrier/center ring gear assembly for damage or excessive wear and install new, as necessary.

-

Pinion gear teeth

-

Pinion gear surfaces

-

Pinion gear bearings

-

Spline teeth

-

Thrust bearing surfaces

-

Thrust bearing

-

Pinion gear teeth

|

-

Remove the low/reverse wave spring, clutch pack and pressure plate.

|

-

Inspect the low/reverse clutch pack and pressure plate

surface for damage or excessive wear and install new, if necessary.

|

-

Remove the low One-Way Clutch (OWC).

|

-

NOTICE: Do not clean in water or with water-based solvents. Damage to the component may occur.

NOTE: The low One-Way Clutch (OWC) should not be disassembled.

Clean and inspect the low One-Way Clutch (OWC) for cracks and damaged splines. The internal splined section should rotate clockwise and lock when rotated counterclockwise. If any damage is found or the clutch does not rotate or lock, install a new low One-Way Clutch (OWC).

|

-

Inspect the intermediate (2, 6) clutch surface for

damage. If the surface is burned or worn excessively, install a new low

One-Way Clutch (OWC).

|

-

NOTE: The intermediate (2, 6) clutch is removed with the rear planetary sun gear and shell assembly.

Remove the rear planetary sun gear and shell assembly and remove the intermediate (2, 6) clutch from the assembly.

|

-

Inspect the intermediate (2, 6) clutch surface for damage or excessive wear and install new, if necessary.

|

-

Clean and inspect the rear planetary sun gear and shell assembly for damage or wear and install new, if necessary.

-

Sun gear teeth

-

Shell-to-clutch pack surfaces

-

Bearing surfaces

-

Sun gear teeth

|

-

Remove the pressure plate and the wave spring.

|

-

Inspect the pressure plate surface for damage or excessive wear and install new, if necessary.

|

-

Remove the No. 3 thrust bearing.

|

-

Remove the overdrive/direct clutch assembly.

|

-

NOTE: If the No. 1 thrust bearing is stuck to the overdrive/direct clutch assembly, remove the No. 1 thrust bearing from the overdrive/direct clutch assembly.

Remove the No. 1 thrust bearing.

|

-

Remove the intermediate (2, 6) clutch apply ring.

|

-

Remove the clutch support tower bolts and the clutch support tower.

|

-

NOTE: Note the location of the snap ring gap for assembly.

Remove the intermediate (2, 6) clutch return spring snap ring.

|

-

NOTE: Note the position of the return spring for assembly.

Remove the intermediate (2, 6) clutch return spring.

|

-

NOTE: Note the position of the intermediate clutch piston for assembly.

Remove the intermediate (2, 6) clutch piston.

Use the General Equipment: Long Nose Pliers

|

-

Remove and discard the clutch feed seals.

|

-

Remove the manual control lever nut and the manual control lever from the manual control shaft.

|

-

NOTICE: Do not drive the manual control shaft pin through the manual control shaft. The manual control shaft pin will contact the transmission case causing damage to the transmission case.

Using the special tool, pull the manual control shaft pin out of the manual control shaft.

Use Special Service Tool: 211-061 (T78P-3504-N1) Remover, Roll Pin.

|

-

Remove the manual control shaft.

|

-

Remove the TR sensor and the park pawl actuator rod and remove the park pawl actuator rod from the TR sensor.

|

-

Remove and discard the manual control shaft seal.

Use the General Equipment: Flat Headed Screw Driver

|

-

Remove and discard the LH halfshaft seal.

|

-

-

NOTICE: If the LH transmission case bushing or the LH halfshaft bushing surface shows signs of excessive wear or damage, a new LH transmission case bushing and a new LH halfshaft must be installed, or excessive noise or transmission failure can occur.

Clean and inspect the LH transmission case bushing and the bushing surface on the LH halfshaft for damage or excessive wear. If the LH transmission case bushing or the LH halfshaft shows signs of excessive wear or damage, install new components.

Refer to: Transmission Case (307-01A Automatic Transmission - 6-Speed Automatic Transmission – 6F35, Disassembly and Assembly of Subassemblies).

-

NOTICE: Do not use metal scrapers, wire brushes, power abrasive discs, or other abrasive means to clean sealing surfaces. These tools cause scratches and gouges which make leak paths.

Make sure that the mating faces are clean and free of foreign material.

Refer to: RTV Sealing Surface Cleaning and Preparation (303-00 Engine System - General Information, General Procedures).

-

|

-

Remove the pump-to-torque converter housing bolts and the pump and filter assembly.

|

-

Remove and discard the RH halfshaft seal.

|

-

-

Inspect the torque converter housing and the

differential ring gear for damage or excessive wear. If the differential

ring gear shows signs of excessive wear or damage replace the

differential ring gear.

Refer to: Transmission Case (307-01A Automatic Transmission - 6-Speed Automatic Transmission – 6F35, Disassembly and Assembly of Subassemblies).

-

NOTICE: Do not use metal scrapers, wire brushes, power abrasive discs, or other abrasive means to clean sealing surfaces. These tools cause scratches and gouges which make leak paths.

Make sure that the mating faces are clean and free of foreign material.

Refer to: RTV Sealing Surface Cleaning and Preparation (303-00 Engine System - General Information, General Procedures).

-

Inspect the torque converter housing and the

differential ring gear for damage or excessive wear. If the differential

ring gear shows signs of excessive wear or damage replace the

differential ring gear.

|

-

NOTE: Note the orientation of the transmission fluid filter to the fluid pump assembly.

Rotate the transmission fluid filter 90 degrees clockwise and pull the transmission fluid filter out of the pump assembly.

|

-

Remove the magnet from the transmission fluid filter and discard the transmission fluid filter.

|

-

Assemble the special tools and remove and discard the input shaft seal.

Use Special Service Tool: 100-001 (T50T-100-A) Slide Hammer. , 303-D011 (D80L-100-G) Actuator Pin (Dia 3/16). , 303-D019 (D80L-100-Q) Collet, 3/4 to 7/8.

|

-

Remove the pump assembly-to-torque converter housing O-ring seal.

|

-

Remove the torque converter hub seal snap ring.

|

-

Using a dent puller, remove the torque converter hub seal.

Use the General Equipment: Puller

|

-

Position the pump assembly in the torque converter

housing and install 2 pump-to-torque converter housing bolts hand-tight.

|

-

Loosen the pump bolts.

|

-

Remove the pump-to-torque converter housing bolts and the pump assembly from the torque converter housing.

|

-

Remove the pump bolts and separate the pump assembly halves.

|

-

NOTE: The dot on the inner pump gear faces up.

Remove the pump gears.

|

-

Compress the main pressure regulator valve spring with a screwdriver and remove the retainer with a magnet.

Use the General Equipment: Flat Headed Screw Driver

Use the General Equipment: Magnetic Socket

|

-

Install a M4 bolt in the valve and remove the main pressure regulator valve assembly.

|

-

Compress the TCC control valve spring with a screw driver and remove the retainer with a magnet.

Use the General Equipment: Flat Headed Screw Driver

Use the General Equipment: Magnetic Socket

|

-

Remove the TCC control valve assembly.

|

-

Clean and dry all of the pump assembly components.

-

Inspect the inner and the outer pump gears for damage or excessive wear and install new, if necessary.

|

-

Inspect the pump housing for damage or excessive wear and install new, as necessary.

-

Inner and outer pump gear to pump housing surface.

-

Inner and outer pump gear to pump housing surface.

|

-

Inspect the torque converter hub bushing for damage or excessive wear and install new, as necessary.

|

-

-

Inspect the aluminum pump housing near the TCC control valve for scoring or blockage.

-

Using a straight edge, inspect the aluminum pump housing near the TCC

control valve for evidence of any surface warping possibly causing

internal pressure leaks. Inspect the hydraulic passages for blockage.

-

Inspect the aluminum pump housing near the TCC control valve for scoring or blockage.

|

-

NOTE: Make sure the valves and the pump housing are clean and dry.

Install the TCC control valve and the main pressure regulator valve in the pump housing. Verify each valve moves freely in the pump housing bore and falls out under its own weight.

|

-

Using a straight edge, inspect the pump housing for evidence of surface warping at the case to pump seal area.

|

-

Inspect the stator bushing for damage or excessive wear and install new, as necessary.

|

-

Inspect the turbine shaft support bushing for wear or

scoring that might cause pressure leaks and install new, as necessary.

|

-

NOTE: The TCC control valve retainer is shown assembled in the pump body, the main pressure regulator valve retainer is similar.

Assemble the TCC control valve assembly and main pressure regulator valve assembly and install the valves in the pump. Compress the valve springs with a screw driver and install the retainers.

|

-

NOTE: The dot on the inner pump gear faces up.

Install the pump gears.

|

-

Position the stator support on the pump housing and install the pump bolts hand-tight.

|

-

Install the pump assembly in the torque converter

housing and install 2 pump-to-torque converter housing bolts hand-tight.

|

-

Tighten the pump bolts.

Torque: 89 lb.in (10 Nm)

|

-

Remove the pump-to-torque converter housing bolts and the pump assembly from the torque converter housing.

|

-

Install a new torque converter hub seal on the special tool.

Use Special Service Tool: 307-627 Installer, Converter Seal.

|

-

Using the special tool, install a new torque converter hub seal.

Use Special Service Tool: 307-627 Installer, Converter Seal.

|

-

Install the torque converter hub seal snap ring.

|

-

Install a new pump assembly-to-torque converter housing O-ring seal.

|

-

Install a new input shaft seal on the special tool.

Use Special Service Tool: 307-723 Installer, Turbine Seal.

|

-

Using the special tool, install the input shaft seal.

Use Special Service Tool: 307-723 Installer, Turbine Seal.

|

-

Install a new O-ring on a new transmission fluid filter and lubricate it with transmission fluid.

Material: Motorcraft® MERCON® LV Automatic Transmission Fluid / XT-10-QLVC (WSS-M2C938-A) (MERCON® LV, )

|

-

Install the magnet on the transmission fluid filter.

|

-

Install the new transmission fluid filter.

-

Position the transmission fluid filter in the pump assembly.

-

Rotate the transmission fluid filter counterclockwise 90 degrees.

-

Position the transmission fluid filter in the pump assembly.

|

-

NOTICE: The piston return spring, snap ring or snap ring retainer from the low/reverse clutch side of the center support are not interchangeable with the forward clutch side of the center support. When disassembling the center support, be careful not to mix the components from the low/reverse clutch side with the forward clutch side of the center support. Failure to assemble the center support with the components in the correct side will result in damage to the center support, low/reverse or forward clutch.

NOTE: The low/reverse clutch piston in the center support is the side of the center support with the long legs.

Using the special tool and a press, compress the low/reverse clutch return spring and remove the snap ring and the snap ring retainer.

Use Special Service Tool: 307-630 Center Support Piston Spring Tool.

Use the General Equipment: Hydraulic Press

|

-

Remove the low/reverse clutch return spring.

|

-

Apply 483 kPa (70 psi) of air pressure to the

low/reverse clutch piston port and remove the low/reverse clutch piston.

|

-

NOTE: The forward clutch piston in the center support is the side of the center support with the short legs.

Using the special tool and a press, compress the forward (1,2, 3, 4) clutch return spring and remove the snap ring and the snap ring retainer.

Use Special Service Tool: 307-630 Center Support Piston Spring Tool.

Use the General Equipment: Hydraulic Press

|

-

Remove the return spring from the forward (1, 2, 3, 4) clutch piston.

|

-

Apply 483 kPa (70 psi) of air pressure to the forward

(1, 2, 3, 4) clutch piston port and remove the forward (1, 2, 3, 4)

clutch piston.

|

-

Clean and inspect the center support for damage. Install a new center support if necessary.

|

-

NOTE: The forward clutch piston in the center support is the side of the center support with the short legs.

Install the special tools on the forward clutch piston side of the center support.

Use Special Service Tool: 307-628 Protector, Low Reverse Piston Seal. , 307-629 Protector, Low Reverse / 1-2-3-4 Piston Seal.

|

-

Lubricate the sealing surfaces of the forward (1, 2, 3, 4) clutch piston with petroleum jelly.

|

-

Position the forward (1, 2, 3, 4) clutch piston on the special tools and push it down into the center support.

Use Special Service Tool: 307-628 Protector, Low Reverse Piston Seal. , 307-629 Protector, Low Reverse / 1-2-3-4 Piston Seal.

|

-

NOTICE: The piston return spring, snap ring or snap ring retainer from the low/reverse clutch side of the center support are not interchangeable with the forward clutch side of the center support. When assembling the center support, be careful not to mix the components from the low/reverse clutch side with the forward clutch side of the center support. Failure to assemble the center support with the components in the correct side will result in damage to the center support, low/reverse or forward clutch.

Install the forward (1, 2, 3, 4) clutch piston return spring.

|

-

Using the special tools and a press, compress the

forward (1,2, 3, 4) clutch return spring and install the snap ring

retainer and the snap ring.

Use Special Service Tool: 307-630 Center Support Piston Spring Tool.

Use the General Equipment: Hydraulic Press

|

-

Inspect the snap ring to be sure it is seated in the groove on the center support.

Use the General Equipment: Flat Headed Screw Driver

|

-

Turn the center support over and install the special tools on the low/reverse piston side of the center support.

Use Special Service Tool: 307-628 Protector, Low Reverse Piston Seal.

|

-

Lubricate the sealing surfaces of the low/reverse piston with petroleum jelly.

|

-

Position the low/reverse clutch piston on the special tools and push it down into the center support.

Use Special Service Tool: 307-628 Protector, Low Reverse Piston Seal.

|

-

Install the low/reverse piston return spring.

|

-

Using the special tools and a press, compress the

low/reverse clutch return spring and install the snap ring retainer and

the snap ring.

Use Special Service Tool: 307-630 Center Support Piston Spring Tool.

Use the General Equipment: Hydraulic Press

|

-

Inspect the snap ring to be sure it is seated in the groove on the center support.

Use the General Equipment: Flat Headed Screw Driver

|

-

Remove and discard the 4 Teflon® seals.

|

-

Clean and inspect the clutch support tower for damage. Install a new clutch support tower if damaged.

|

-

Install the special tool on the clutch support tower and

adjust the special tool to align the bottom edge of the tool with the

top edge of the bottom Teflon® seal groove.

Use Special Service Tool: 307-578 Input Shaft Support Seal Installer (Back Plate, Multiple rings).

|

-

Install a new Teflon® seal on the special tool.

Use Special Service Tool: 307-578 Input Shaft Support Seal Installer (Back Plate, Multiple rings).

|

-

Install the special tool 307-578/2 over 307-578/3. Using

the special 307-578/2, slide the Teflon® seal over the clutch support

tower and into the groove.

Use Special Service Tool: 307-578 Input Shaft Support Seal Installer (Back Plate, Multiple rings).

|

-

Remove tools and repeat steps for the other 3 Teflon® seals.

Use Special Service Tool: 307-578 Input Shaft Support Seal Installer (Back Plate, Multiple rings).

|

-

Install the special tool on the clutch support tower to size the 4 Teflon® seals.

Use Special Service Tool: 307-578 Input Shaft Support Seal Installer (Back Plate, Multiple rings).

|

-

Remove the input shaft snap ring.

|

-

Remove the input shaft.

|

-

Remove the overdrive (4, 5, 6) clutch hub.

|

-

Remove the overdrive (4, 5, 6) clutch hub, No. 2 thrust bearing.

|

-

Remove the overdrive (4, 5, 6) clutch snap ring.

|

-

Remove the overdrive (4, 5, 6) clutch pressure plate and clutch assembly.

|

-

Inspect the clutch plate and pressure plate surfaces for damage or excessive wear.

|

-

Install the special tools on the balance piston.

Use Special Service Tool: 307-584 2-6 Spring Compressor. , 307-589 Overdrive clutch and balance piston service set.

|

-

Using a press, compress the overdrive (4, 5, 6) clutch return spring and remove the snap ring.

Use Special Service Tool: 307-584 2-6 Spring Compressor. , 307-589 Overdrive clutch and balance piston service set.

Use the General Equipment: Hydraulic Press

|

-

Remove and discard the balance piston.

|

-

Remove the overdrive (4, 5, 6) piston return spring.

|

-

Install the clutch support tower in the transmission case and install the clutch support tower bolts.

Torque: 106 lb.in (12 Nm)

|

-

Remove the special tool.

Remove Special Service Tool: 307-578 Input Shaft Support Seal Installer (Back Plate, Multiple rings).

|

-

Install the No. 1 overdrive/direct clutch assembly thrust bearing.

|

-

Position the overdrive/direct clutch assembly in the transmission case.

|

-

Apply compressed air to the overdrive (4, 5, 6) clutch

piston port and remove the overdrive (4, 5, 6) clutch piston.

|

-

Remove the overdrive/direct clutch assembly from the transmission case.

|

-

Remove and discard the overdrive (4, 5, 6) clutch piston seal from the overdrive/direct clutch assembly.

|

-

Remove and discard the seals from the overdrive (4, 5, 6) clutch piston.

|

-

NOTICE: Only compress the direct clutch piston return spring far enough to take the tension from the direct clutch cylinder off the snap ring. If the piston is compressed too far, the piston alignment tab may be broken off.

Install the special tools on the direct (3, 5, R) clutch cylinder. Using a press, compress the direct (3, 5, R) clutch piston return spring, and remove the snap ring.

-

Do not contact the overdrive/direct clutch hub and shaft assembly with the direct (3, 5, R) clutch cylinder.

-

Remove the snap ring.

Use Special Service Tool: 307-584 2-6 Spring Compressor. , 307-589 Overdrive clutch and balance piston service set.

Use the General Equipment: Hydraulic Press

-

Do not contact the overdrive/direct clutch hub and shaft assembly with the direct (3, 5, R) clutch cylinder.

|

-

Remove the direct (3, 5, R) clutch cylinder.

|

-

Remove and discard the direct (3, 5, R) clutch piston.

|

-

NOTE: Note the position of the return spring for assembly. The flat side faces down.

Remove the direct (3, 5, R) clutch piston return spring.

|

-

Remove the direct (3, 5, R) clutch snap ring.

-

Slightly lift up on the direct (3, 5, R) clutch so that the snap ring floats freely.

-

Using a tool, compress the snap ring.

-

Allow the direct (3, 5, R) clutch and pressure plate

to drop so that the snap ring is out of the pressure plate groove.

-

Remove the snap ring.

-

Slightly lift up on the direct (3, 5, R) clutch so that the snap ring floats freely.

|

-

Remove the direct (3, 5, R) clutch pressure plate, clutch pack and wave spring.

|

-

Inspect the clutch plate and pressure plate surfaces for damage or excessive wear.

|

-

Remove and discard the direct (3, 5, R) clutch piston seals.

|

-

Clean and inspect the overdrive/direct clutch assembly

for damage or excessive wear and install new components as necessary.

|

-

Install new direct (3, 5, R) clutch piston seals and lubricate the seals with petroleum jelly.

|

-

Install the direct (3, 5, R) clutch wave spring.

|

-

Soak the direct (3, 5, R) clutch pack in transmission fluid.

Material: Motorcraft® MERCON® LV Automatic Transmission Fluid / XT-10-QLVC (WSS-M2C938-A) (MERCON® LV, )

|

-

Install the direct (3, 5, R) clutch assembly and pressure plate.

|

-

Install the direct (3, 5, R) clutch snap ring.

-

Compress the snap ring.

- Lift the direct (3, 5, R) clutch so that the snap ring is in the groove of the pressure plate.

- Release the tension on the snap ring.

-

Compress the snap ring.

|

-

NOTE: Install the direct (3, 5, R) clutch piston return spring with the flat side facing down.

Install the direct (3, 5, R) clutch piston return spring.

|

-

Lubricate a new direct (3, 5, R) clutch piston with petroleum jelly and install the piston.

|

-

Install the direct (3, 5, R) clutch cylinder.

|

-

NOTICE: Only compress the direct clutch piston return spring far enough to take the tension from the direct clutch cylinder off the snap ring. If the piston is compressed too far, the piston alignment tab may be broken off.

Install the special tools on the direct (3, 5, R) clutch cylinder. Using a press, compress the direct (3, 5, R) clutch piston return spring, and install the snap ring.

-

Do not contact the overdrive/direct clutch hub and shaft assembly with the direct (3, 5, R) clutch cylinder.

-

Install the snap ring.

Use Special Service Tool: 307-584 2-6 Spring Compressor. , 307-589 Overdrive clutch and balance piston service set.

Use the General Equipment: Hydraulic Press

-

Do not contact the overdrive/direct clutch hub and shaft assembly with the direct (3, 5, R) clutch cylinder.

|

-

Install new seals on the overdrive (4, 5, 6) clutch piston and lubricate the seals with petroleum jelly.

|

-

Install a new overdrive (4, 5, 6) clutch piston inner seal and lubricate the seal with petroleum jelly.

|

-

Position the overdrive (4, 5, 6) clutch piston in place.

|

-

Using the special tools, install the overdrive (4, 5, 6)

clutch piston into the overdrive/direct clutch assembly by hand.

Use Special Service Tool: 307-589 Overdrive clutch and balance piston service set.

|

-

NOTE: Holes face up on the overdrive (4, 5, 6) clutch piston return spring.

Install the overdrive (4, 5, 6) clutch piston return spring.

|

-

Lubricate the seals on a new balance piston and position the piston in place.

|

-

Install the special tools on the balance piston.

Use Special Service Tool: 307-584 2-6 Spring Compressor. , 307-589 Overdrive clutch and balance piston service set.

|

-

Using a press, compress the overdrive (4, 5, 6) clutch return spring and install the snap ring.

Use Special Service Tool: 307-584 2-6 Spring Compressor. , 307-589 Overdrive clutch and balance piston service set.

Use the General Equipment: Hydraulic Press

|

-

Install the No. 2 thrust bearing.

|

-

Install the overdrive (4, 5, 6) clutch hub.

|

-

Soak the overdrive (4, 5, 6) clutch pack in transmission fluid.

Material: Motorcraft® MERCON® LV Automatic Transmission Fluid / XT-10-QLVC (WSS-M2C938-A) (MERCON® LV, )

|

-

Install the overdrive (4, 5, 6) clutch pack.

|

-

Install the overdrive (4, 5, 6) clutch pressure plate.

|

-

Install the overdrive (4, 5, 6) clutch snap ring.

|

-

Install the input shaft.

|

-

While holding the input shaft in place, install the snap ring.

|

-

Position the overdrive/direct clutch assembly in the

transmission case, install the special tool or a dial indicator and

position the plunger on the overdrive (4, 5, 6) clutch pressure plate.

Use Special Service Tool: 100-002 (TOOL-4201-C) Holding Fixture with Dial Indicator Gauge.

|

-

NOTE: The dial indicator plunger is positioned on the overdrive (4, 5, 6) clutch pressure plate.

Apply 483 kPa (70 psi) of air pressure to the overdrive (4, 5, 6) clutch piston port while recording the clutch pack clearance on the Dial Indicator. The clearance should be between 0.950 mm (0.037 in) and 1.778 mm (0.07 in). If the clearance is out of range, check the overdrive (4, 5, 6) clutch pack for correct installation. If the overdrive (4, 5, 6) clutch pack is correctly installed, install a new overdrive (4, 5, 6) clutch pack.

Use Special Service Tool: 100-002 (TOOL-4201-C) Holding Fixture with Dial Indicator Gauge.

|

-

Position the plunger on one of the top direct (3, 5, R)

clutch plate tabs. Apply 483 kPa (70 psi) of air pressure to the direct

(3, 5, R) clutch piston port while recording the clutch pack clearance

on Dial Indicator. The clearance should be between 1.71 mm (0.067 in)

and 3.61 mm (0.142 in). If the clearance is out of range, check the

direct (3, 5, R) clutch pack for correct installation. If the direct (3,

5, R) clutch pack is correctly installed, install a new direct (3, 5,

R) clutch pack.

Use Special Service Tool: 100-002 (TOOL-4201-C) Holding Fixture with Dial Indicator Gauge.

|

-

Remove the special tool, overdrive/direct clutch

assembly and the No. 1 overdrive/direct clutch assembly thrust bearing.

Use Special Service Tool: 100-002 (TOOL-4201-C) Holding Fixture with Dial Indicator Gauge.

|

-

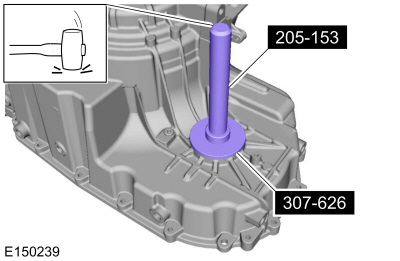

Assemble the special tools. Install a new LH halfshaft seal on the special tool.

Use Special Service Tool: 205-153 (T80T-4000-W) Handle. , 307-626 Installer, Differential Seal.

|

-

Using the special tools, install the new LH halfshaft seal in the transmission case.

Use Special Service Tool: 205-153 (T80T-4000-W) Handle. , 307-626 Installer, Differential Seal.

|

-

Install a new manual control shaft seal on the special tool.

Use Special Service Tool: 307-581 Manual lever seal installer.

|

-

Using the special tool, install the new manual control shaft seal in the transmission case.

Use Special Service Tool: 307-581 Manual lever seal installer.

|

-

Install the special tool.

Use Special Service Tool: 307-632 Protector, 2-6 Piston Seal.

|

-

Lubricate the seals on the intermediate (2, 6) clutch piston with transmission fluid.

Material: Motorcraft® MERCON® LV Automatic Transmission Fluid / XT-10-QLVC (WSS-M2C938-A) (MERCON® LV, )

|

-

NOTICE: Be sure the bleed hole is aligned in the correct position as noted during disassembly or damage to the transmission can occur.

Install the intermediate (2, 6) clutch piston on the seal protector with the bleed hole aligned at the top of the transmission case.

|

-

Position the intermediate (2, 6) clutch piston return spring on the piston to align the piston before pushing it in its bore. The tabs of the return spring should fit into the indentions of the piston and the 2 outer tabs should be at the clockwise most position of the open area at the bottom of the transmission case. The bleed hole on the piston should be aligned between the inner double tabs of the return spring.

-

Inner double tabs

-

Bleed hole

-

Outer tabs

-

Inner double tabs

|

-

Remove the intermediate (2, 6) clutch piston return spring.

|

-

Install the special tool on the intermediate (2, 6)

clutch piston. Push the intermediate (2, 6) clutch piston into the

clutch cylinder by hand.

Use Special Service Tool: 307-584 2-6 Spring Compressor.

|

-

NOTICE: Be sure the return spring is positioned correctly with the forward clutch bleed hole aligned between the inner double tabs and the outer tab in the clockwise most position of the slot at the bottom of the case or damage to the transmission can occur.

Install the intermediate (2, 6) clutch piston return spring. The tabs of the return spring should fit into the indentions of the piston and the 2 outer tabs should be at the clockwise most position of the slot at the bottom of the case. The bleed hole on the piston should be aligned between the inner double tabs of the return spring.

-

Inner double tabs

-

Bleed hole

-

Outer tabs

-

Inner double tabs

|

-

NOTICE: Be sure the snap ring is aligned with the gap facing the front of the transmission or damage to the transmission can occur. The front of the transmission is where the low/reverse and forward (1, 2, 3,4) clutch hydraulic ports are located.

Position the snap ring in place. Align the gap of the snap ring to face the front of the transmission.

-

Snap ring

-

Snap ring gap

-

Low/reverse and forward (1, 2, 3, 4) clutch hydraulic ports (located at the front of the transmission case)

-

Snap ring

|

-

Install the special tool on the transmission case to center the intermediate (2, 6) clutch return spring.

Use Special Service Tool: 307-633 2-6 Piston return spring Comp.

|

-

Install the special tool on the snap ring.

Use Special Service Tool: 307-633 2-6 Piston return spring Comp.

|

-

Install the special tool on the transmission case.

Use Special Service Tool: 307-574 Forward Clutch Spring Compressor.

|

-

NOTICE: Be sure the return spring is centered or it can bind on the snap ring groove and cause damage to the transmission case.

Using the special tools, install the intermediate (2, 6) clutch snap ring in the groove.

Use Special Service Tool: 307-574 Forward Clutch Spring Compressor. , 307-633 2-6 Piston return spring Comp.

|

-

Install the intermediate (2, 6) clutch apply ring. Tap the ring in place.

|

-

NOTICE: Be sure to install the No. 1 thrust bearing with the flat side facing up or damage to the transmission can occur.

Install the No. 1 thrust bearing with the flat side facing up.

|

-

Install the overdrive/direct clutch assembly.

|

-

NOTICE: Be sure to install the No. 3 thrust bearing with the flat side facing down or damage to the transmission can occur.

Install the No. 3 thrust bearing with the flat side facing down.

|

-

Install the direct/intermediate clutch hub and rear sun gear assembly.

|

-

Install the intermediate (2, 6) wave spring assembly.

|

-

Soak the intermediate (2, 6) clutch assembly in transmission fluid.

Material: Motorcraft® MERCON® LV Automatic Transmission Fluid / XT-10-QLVC (WSS-M2C938-A) (MERCON® LV, )

|

-

Install the intermediate (2, 6) clutch assembly, temporarily reversing the top friction and steel plates for the clutch stack-up measurement.

-

Steel plate

-

Friction plate

-

Steel plate

|

-

Install the special tool on the transmission case.

Use Special Service Tool: 307-300 Gauge Bar, Shim Selection.

|

-

Using a depth gauge, measure and record as measurement

A, the distance from the special tool to the top of the intermediate (2,

6) clutch pack at 3 different points and average the 3 distances.

Use Special Service Tool: 307-300 Gauge Bar, Shim Selection.

|

-

Using a depth gauge, measure and record as measurement

B, the distance from the top of the special tool to the transmission

case step above the intermediate (2, 6) clutch.

Use Special Service Tool: 307-300 Gauge Bar, Shim Selection.

|

-

Subtract measurement B from measurement A The clearance

should be between 0.240 mm (0.009in) and 2.60 mm (0.102 in). If the

clearance is out of range, check the intermediate (2, 6) clutch pack for

correct installation. If the intermediate (2, 6) clutch pack is

correctly installed, install a new clutch pack.

Description Reading Measurement A Measurement B Subtract measurement B from measurement A and check to see if it is within range of 0.240mm (0.009 in) and 2.60 mm (0.102 in)

-

Remove the top intermediate (2, 6) clutch friction and steel plate.

|

-

NOTE: When the intermediate (2, 6) clutch is correctly installed, a friction plate is on top.

Install the top intermediate (2, 6) clutch friction and steel plate correctly back in the transmission case.

-

Friction plate

-

Steel plate

-

Friction plate

|

-

Install the One-Way Clutch (OWC) assembly.

|

-

Install the rear planetary carrier/center ring gear assembly.

|

-

NOTE: Note the position of the low/reverse pressure plate. When installing the center support, the long support legs must fit through the low/reverse pressure plate and rest on the One-Way Clutch (OWC).

Position the low/reverse pressure plate so that the center support legs fit through the pressure plate and rest on the One-Way Clutch (OWC) and install the low/reverse pressure plate.

|

-

Soak the low/reverse clutch in transmission fluid.

Material: Motorcraft® MERCON® LV Automatic Transmission Fluid / XT-10-QLVC (WSS-M2C938-A) (MERCON® LV, )

|

-

Align the low/reverse clutch pack with the pressure plate and install it in the transmission case temporarily reversing the wave spring and top steel plate.

-

Steel plate.

-

Wave spring.

-

Steel plate.

|

-

Install the special tool on the side of the center support with the long support legs.

Use Special Service Tool: 307-300 Gauge Bar, Shim Selection.

|

-

Using a depth gauge, measure and record as measurement

A, the distance from the top of the special tool to the contact surface

of the low/reverse clutch piston.

Use Special Service Tool: 307-300 Gauge Bar, Shim Selection.

|

-

Using a depth gauge, measure and record as measurement

B, the distance from the top of the special tool to the leg surface of

the center support.

Use Special Service Tool: 307-300 Gauge Bar, Shim Selection.

|

-

Subtract measurement B from measurement A and record as measurement C.

Description Reading Measurement A Measurement B Subtract measurement B from measurement A and record as measurement C

-

Install the special tool on the transmission case.

Use Special Service Tool: 307-300 Gauge Bar, Shim Selection.

|

-

Using a depth micrometer, measure and record as

measurement D, the distance from the special tool to the top of the

One-Way Clutch (OWC).

Use Special Service Tool: 307-300 Gauge Bar, Shim Selection.

|

-

Using a depth gauge, measure and record as measurement

E, the distance from the top of special tool to the top of the

low/reverse clutch at 3 different points and average the 3 distances.

Use Special Service Tool: 307-300 Gauge Bar, Shim Selection.

|

-

Subtract measurement E from measurement D and record as measurement F.

Description Reading Measurement D Measurement E Subtract measurement E from measurement D and record as measurement F

-

Subtract measurement F from measurement C to get the

low/reverse clutch clearance. The clearance should be between 0.406 mm

(0.015 in) and 2.000 mm (0.078 in). If the clearance is out of range,

check the low/reverse clutch pack for correct installation. If the

low/reverse clutch pack is correctly installed, install a new clutch

pack.

Description Reading Measurement C Measurement F Subtract measurement F from measurement C and check to see if it is within range of 0.406mm (0.015 in) and 2.000 mm (0.078 in)

-

NOTE: When the low/reverse clutch is correctly installed, the wave spring is on top.

Remove the top low/reverse clutch steel plate and wave spring and correctly install the plates back in the transmission case.

-

Wave spring

-

Steel plate

-

Wave spring

|

-

NOTE: Be sure the center support is installed with the long support legs facing down and the feed holes facing the front of the transmission.

Install the center support with the long legs facing down and the feed holes aligned with the feed holes in the transmission case.

-

Long center support legs face down

-

Feed holes face the front of the transmission case

-

Long center support legs face down

|

-

-

Install the No. 5 thrust bearing

-

Install the No. 6 thrust bearing

-

Install the No. 5 thrust bearing

|

-

Install the center planetary sun gear.

|

-

Install the center carrier/front ring gear assembly.

|

-

-

Install the No. 7 thrust bearing

-

Install the No. 8 thrust bearing

-

Install the No. 7 thrust bearing

|

-

Install the front planetary/rear ring gear assembly.

|

-

Install the forward (1, 2, 3, 4) clutch wave spring.

|

-

Soak the forward (1, 2, 3, 4) clutch pack in transmission fluid.

Material: Motorcraft® MERCON® LV Automatic Transmission Fluid / XT-10-QLVC (WSS-M2C938-A) (MERCON® LV, )

|

-

Install the forward (1, 2, 3, 4) clutch pack.

|

-

Install the forward (1, 2, 3, 4) clutch pressure plate.

|

-

NOTICE: Be sure to install the forward (1, 2, 3, 4) clutch beveled snap ring with the flat side facing down or the snap ring can come loose, causing damage to the transmission.

Install the forward (1, 2, 3, 4) clutch beveled snap ring with the flat side down with the gap facing the front of the transmission.

|

-

Seat the snap ring in the snap ring groove.

Use the General Equipment: Flat Headed Screw Driver

|

-

Install the special tool or a dial indicator on the

transmission case and position the plunger on the top forward (1, 2, 3,

4) clutch friction plate.

Use Special Service Tool: 100-002 (TOOL-4201-C) Holding Fixture with Dial Indicator Gauge.

|

-

Install the new low/reverse and forward (1, 2, 3, 4) clutch main control-to-transmission case seals.

|

-

Apply 483 kPa (70 psi) of air pressure to the forward

(1, 2, 3, 4) clutch piston port while recording the clutch pack

clearance on the dial indicator. The clearance should be between 0.076

mm (0.002in) and 1.840 mm (0.072 in). If the clearance is out of range,

check the forward (1, 2, 3, 4) clutch pack for correct installation and

the transmission for correct assembly. If the forward (1, 2, 3, 4)

clutch pack is correctly installed, install a new forward (1, 2, 3, 4)

clutch pack.

Use Special Service Tool: 100-002 (TOOL-4201-C) Holding Fixture with Dial Indicator Gauge.

|

-

NOTE: Make sure the front planetary sun gear and shell assembly is fully engaged into both forward clutch friction plates.

Install the front planetary sun gear and shell assembly.

|

-

Install the park pawl.

|

-

Install the park pawl pin and spring.

|

-

Install the park pawl actuator rod in the TR sensor. Position the park pawl aside and position the park pawl actuator rod and the TR sensor in the transmission case.

|

-

Install the manual control shaft and align the manual control shaft pin holes.

|

-

Install the manual control shaft pin.

Use the General Equipment: Punch

|

-

NOTICE: Make sure to hold the manual control lever while tightening the manual control lever nut or damage to the manual control lever and park components will occur.

Install the manual control lever and the manual control lever nut.

Torque: 18 lb.ft ( 24 Nm)

|

-

Install the 5 new clutch feed seals.

|

-

Position the transmission fluid baffle in place and install the transmission fluid baffle bolts.

Torque: 106 lb.in (12 Nm)

|

-

Position the fluid reservoir in place and install the fluid reservoir bolts.

Torque: 106 lb.in (12 Nm)

|

-

-

Install the No. 12 thrust bearing

-

Install the No. 10 thrust bearing

-

Install the No. 12 thrust bearing

|

-

-

Simultaneously install the drive/driven sprocket and chain assembly.

-

Lightly tap on the driven sprocket to be sure it is fully seated in the case.

-

Simultaneously install the drive/driven sprocket and chain assembly.

|

-

-

Install the No. 13 thrust washer

-

Install the No. 11 thrust bearing

-

Install the No. 13 thrust washer

|

-

Install the differential transmission fluid baffle.

|

-

Install the differential sun gear.

|

-

Install the differential assembly.

|

-

Install the No. 15 thrust bearing

|

-

Install the special tool on the input shaft.

Use Special Service Tool: 307-635 Protector, Turbine Shaft Seal.

|

-

NOTE: FWD Vehicles.

Assemble the special tools and install a new RH halfshaft seal on the special tool.

Use Special Service Tool: 205-153 (T80T-4000-W) Handle. , 307-718 Installer, Axle Seal.

|

-

NOTE: FWD Vehicles.

Using the special tools, install the new RH halfshaft seal.

Use Special Service Tool: 205-153 (T80T-4000-W) Handle. , 307-718 Installer, Axle Seal.

|

-

NOTE: AWD Vehicles.

Assemble the special tools and install a new RH halfshaft seal on the special tool.

Use Special Service Tool: 205-153 (T80T-4000-W) Handle. , 307-718 Installer, Axle Seal.

|

-

NOTE: AWD Vehicles.

Using the special tools, install the new RH halfshaft seal.

Use Special Service Tool: 205-153 (T80T-4000-W) Handle. , 307-718 Installer, Axle Seal.

|

-

Install the pump and filter assembly in the torque

converter housing and install the pump-to-torque converter housing

bolts.

Torque: 26 lb.ft (35 Nm)

|

-

NOTE: Be sure the sealing surfaces of the torque converter housing and the transmission housing are free of oil before applying silicone.

Apply silicone to the sealing surface of the transmission case.

Material: Motorcraft® Ultra Silicone Sealant / TA-29 (WSS-M4G323-A8)

|

-

Install the torque converter housing on the transmission case.

|

-

NOTE: Be sure the torque converter housing stud bolt is in the correct location as noted during disassembly.

Install the torque converter housing bolts and the torque converter housing stud bolt.

Torque: 24 lb.ft (32 Nm)

|

-

Remove the special tool.

Remove Special Service Tool: 307-635 Protector, Turbine Shaft Seal.

|

-

Install the TSS sensor and the TSS sensor bolt.

Torque: 89 lb.in (10 Nm)

|

-

Install the OSS sensor and the OSS sensor bolt.

Torque: 89 lb.in (10 Nm)

|

-

Install the new main control-to-transmission case separator plate and align it on the stud and the guide pin.

|

-

NOTE: Be sure that the manual pin (part of the TR sensor) is correctly installed in the manual valve.

Position the main control assembly in place and align the manual valve on the TR sensor.

|

-

Install the main control nut hand-tight.

|

-

Install the short main control-to-transmission case bolts hand-tight.

|

-

Install the long main control-to-transmission case bolts hand-tight.

|

-

Tighten the main control-to-transmission case bolts and the main control nut in a crisscross pattern.

Torque: 89 lb.in (10 Nm)

|

-

Position the TR sensor detent spring in place with the alignment tab in the alignment hole and install the TR sensor detent spring bolt.

Torque: 115 lb.in (13 Nm)

|

-

NOTE: Be sure the main control-to-cover seal is installed with the holes facing up.

Install the main control-to-cover seal.

|

-

Connect the TR sensor electrical connector.

|

-

Connect the OSS sensor electrical connector.

|

-

NOTICE: Do not use metal scrapers, wire brushes, power abrasive discs, or other abrasive means to clean sealing surfaces. These tools cause scratches and gouges which make leak paths.

Make sure that the mating faces are clean and free of foreign material.

Refer to: RTV Sealing Surface Cleaning and Preparation (303-00 Engine System - General Information, General Procedures).

|

-

Apply silicone to the main control sealing surface of the transmission case.

Material: Motorcraft® Ultra Silicone Sealant / TA-29 (WSS-M4G323-A8)

|

-

NOTE: Install the main control cover stud bolts in the correct location as noted during disassembly.

Install the main control cover and the main control cover bolts and stud bolts.

Torque: 106 lb.in (12 Nm)

|

Auto-Start-Stop

-

Clean and inspect the transmission fluid auxiliary pump supply tube and check ball.

-

Check ball (part of the transmission fluid auxiliary pump supply tube)

-

Check ball (part of the transmission fluid auxiliary pump supply tube)

|

-

Install the transmission fluid auxiliary pump supply tube assembly.

|

-

Install the transmission fluid auxiliary pump gasket.

|

-

Install the transmission fluid auxiliary pump and the new bolts.

Torque: 115 lb.in (13 Nm)

|

All vehicles

-

NOTICE: The torque converter is heavy. Be careful not to drop it or damage will result.

Using the special tools, install the torque converter.

Use Special Service Tool: 307-091 Handle, Torque Converter.

|

-

Install the special tool.

Use Special Service Tool: 307-566 Retainer, Torque Converter.

|

-

Remove the transmission from the bench-mounted holding fixture.

Use Special Service Tool: 307-003 (T57L-500-B) Holding Fixture, Transmission. , 307-625 Fixture, Bench Mounting.

|

-

Remove the special tool.

Use Special Service Tool: 307-625 Fixture, Bench Mounting.

|

Main Control Valve Body. Overhaul

Main Control Valve Body. Overhaul

Special Tool(s) /

General Equipment

307-636Alignment Pins- Valve BodyTKIT-2008ET-FLMTKIT-2008ET-ROW

Flat Headed Screw Driver

Magnetic Socket

Long Nose Pliers

Main Control Valve Body and Solenoid Body

Remove the solenoid body-to-valve body bolts and separate the solenoid body from the valve body...

Transmission Case. Disassembly and Assembly of Subassemblies

Transmission Case. Disassembly and Assembly of Subassemblies

Special Tool(s) /

General Equipment

205-153

(T80T-4000-W)

Handle

206-084Installer, Wheel Speed Sensor RingTKIT-2003-FLM/LMTKIT-2003D-F

307-664Case Bushing InstallerTKIT-2009OP-FLMTKIT-2009OP-ROW

Flat Headed Screw Driver

Hydraulic Press

Materials

Name

Specification

Loctite® 6481835922

WSK-M2G349-A4

DISASSEMBLY

NOTE:

The transm..

Other information:

Ford Fusion 2013–2020 Service Manual: Active Grille Shutter. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. Remove the front bumper cover. Refer to: Front Bumper Cover (501-19 Bumpers, Disassembly and Assembly). On both sides. Remove the pin-type retainers. Remove the bolts. Torque: 53 lb.in (6 Nm) Remove the bolts. ..

Ford Fusion 2013–2020 Service Manual: Brake Vacuum Sensor. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. Remove the battery hold down bolt and plate. Torque: 89 lb.in (10 Nm) Position the battery forward. Disconnect the brake vacuum sensor electrical connector. Remove the brake vacuum sensor. ..

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Starter Motor. Removal and Installation

- Load Carrying

- Automatic Transmission Fluid Check - 1.5L EcoBoost™/2.0L EcoBoost™/2.5L. Automatic Transmission Fluid Check - 2.7L EcoBoost™

- New on site

- Most important about car

Manual Climate Control

Note: Depending on your vehicle option package, the controls may look different from what you see here.