Ford Fusion: Fuel Charging and Controls - Turbocharger - 1.5L EcoBoost (118kW/160PS) – I4 / Turbocharger. Removal and Installation

Special Tool(s) /

General Equipment

| Hose Clamp Remover/Installer |

Materials

| Name |

Specification |

Motorcraft® Metal Brake Parts Cleaner

PM-4-A, PM-4-B |

-

|

Removal

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles. When removing any turbocharger or engine air intake

system component, ensure that no debris enters the system. Failure to

do so may result in damage to the turbocharger.

NOTE:

Removal steps in this procedure may contain installation details.

-

Remove the air cleaner outlet pipe.

Refer to: Air Cleaner Outlet Pipe (303-12A Intake Air Distribution and Filtering - 1.5L EcoBoost (118kW/160PS) – I4, Removal and Installation).

-

Remove the air cleaner.

Refer to: Air Cleaner (303-12A Intake Air Distribution and Filtering - 1.5L EcoBoost (118kW/160PS) – I4, Removal and Installation).

-

-

Remove the CAC intake pipe retaining bolt.

Torque:

71 lb.in (8 Nm)

-

Loosen the CAC intake pipe clamp , then disconnect the CAC intake pipe.

-

Loosen the TC bypass hose clamp , then disconnect the TC bypass hose.

-

Disconnect the TC bypass solenoid valve and IAT sensor electrical connectors.

-

Detach the wiring harness retainers.

-

-

Loosen the TC air outlet pipe clamp.

Torque:

44 lb.in (5 Nm)

-

2. Squeeze the sides of the coupling and disconnect the vacuum tube.

-

Disconnect the crankcase ventilation tube quick release coupling.

Refer to: Quick Release Coupling (310-00A Fuel System - General Information - 1.5L EcoBoost (118kW/160PS) – I4, General Procedures).

-

Disconnect the IAT2 sensor electrical connector and remove the TC air outlet pipe.

-

-

Loosen the TC air inlet pipe clamp.

Torque:

44 lb.in (5 Nm)

-

2. Remove the TC air inlet pipe retaining bolts.

-

Detach the wiring harness retainers and remove the TC air inlet pipe.

Torque:

71 lb.in (8 Nm)

-

Remove the catalytic converter.

Refer to: Catalytic Converter (309-00A Exhaust System - 1.5L EcoBoost (118kW/160PS) – I4, Removal and Installation).

-

Drain the cooling system.

Refer to: Engine Cooling System Draining, Vacuum Filling and Bleeding (303-03A Engine Cooling - 1.5L EcoBoost (118kW/160PS) – I4, General Procedures).

-

-

Disconnect the TC coolant hose clamps and position the TC coolant hoses aside.

-

Remove the TC coolant tube bracket bolt.

Torque:

97 lb.in (11 Nm)

-

Remove the TC coolant tube bracket bolt.

Torque:

17 lb.ft (23 Nm)

-

-

NOTE:

Note the TC coolant tube locations for installation.

Disconnect the TC coolant tube bolt from the TC.

Torque:

89 lb.in (10 Nm)

-

Remove the TC coolant tubes.

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B

-

Remove the TC heat shield bolts, then remove the TC heat shield.

Torque:

89 lb.in (10 Nm)

-

-

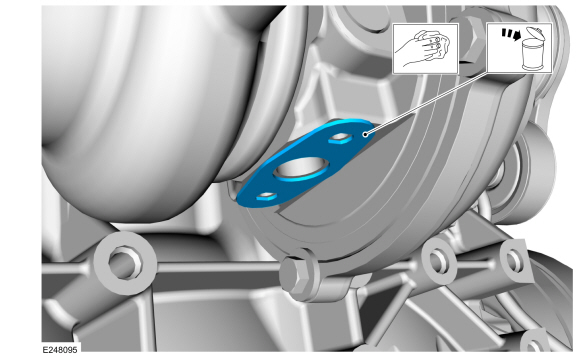

Remove and discard the TC coolant tube O-ring seals.

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B

-

-

Remove the TC oil return tube to TC bolts.

-

Remove the TC oil return tube to engine block bolt, then remove and discard the TC oil return tube.

-

Remove and discard the TC oil return tube gasket. Clean the sealing surface.

-

Disconnect the TC wastegate control hose.

Use the General Equipment: Hose Clamp Remover/Installer

-

Remove the TC oil supply tube bolt , then disconnect the TC oil supply tube.

-

Remove and discard the TC mounting nuts. Remove the TC.

-

Remove the and discard the TC oil supply tube assembly, including the bolt, the sealing washers and the O-rings seals.

Installation

NOTICE:

Make sure that the mating faces are clean and free of foreign material.

-

NOTICE:

Do-not use a metal brush; damage to sealing area will result in leaks.

-

Carefully use a nylon brush to remove the old O-ring

residue and use brake cleaner to rinse the O-ring residue out of the

turbocharger O-ring bore. Inspect the area for deep scratches and

gouges.

-

Install the new TC

oil supply tube assembly, including the new bolt, the new sealing

washers and the new O-ring seals. Lubricate the new O-ring seals with

clean engine oil.

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B

Torque:

19 lb.ft (26 Nm)

-

Replace the TC mounting studs and the gasket.

Torque:

89 lb.in (10 Nm)

-

Install the TC and tighten the TC mounting nuts in the sequence shown.

Torque:

Stage 1:

Tighten in the sequence shown to: :

62 lb.in (7 Nm)

Stage 2:

Tighten in the sequence shown to: :

124 lb.in (14 Nm)

Stage 3:

Tighten in the sequence shown to: :

17 lb.ft (23 Nm)

-

NOTICE:

When installing the oil supply tube, the spigot on

the oil supply tube must be fully engaged to the cylinder head with both

O-rings inserted before the fastener is tightened.

Install the TC oil supply tube, then install and tighten the TC oil supply tube bolt.

Torque:

89 lb.in (10 Nm)

-

Connect the TC wastegate control hose.

Use the General Equipment: Hose Clamp Remover/Installer

-

Install the new TC oil return tube gasket. Lubricate the O-ring seal with clean engine oil.

-

NOTICE:

Do-not use a metal brush; damage to sealing area will result in leaks.

-

Carefully use a nylon brush to remove the old O-ring

residue and use brake cleaner to rinse the O-ring residue out of the

turbocharger tube to engine O-ring bore. Inspect the area for deep

scratches and gouges.

-

Install the new turbocharger oil return tube, then

install and tighten the turbocharger oil return tube bolts.

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B

Torque:

89 lb.in (10 Nm)

-

Install the new the turbocharger coolant tube O-ring seals, then lubricate with clean engine coolant.

-

To install, reverse the removal procedure.

System Operation

Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual. See Section 1 Description and Operation.

Component Description

Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual...

Removal

NOTICE:

Whenever turbocharger air intake system components are

removed, always cover open ports to protect from debris. It is important

that no foreign material enter the system...

Other information:

WARNING: Do not let children play

with the moonroof or leave them

unattended in the vehicle. They may

seriously hurt themselves.

WARNING: When closing the

moonroof, you should verify that it is free

of obstructions and make sure that

children and pets are not in the proximity

of the roof opening...

Special Tool(s) /

General Equipment

204-161

(T97P-1175-A)

Installer, HalfshaftTKIT-1997-LM2TKIT-1997-F/FM2TKIT-1997-FLM2

205-D070

(D93P-1175-B)

Remover, Front Wheel Hub

Removal

Remove the wheel and tire.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation)...

Turbocharger - System Operation and Component Description. Description and Operation

Turbocharger - System Operation and Component Description. Description and Operation Wastegate Control Valve Solenoid. Removal and Installation

Wastegate Control Valve Solenoid. Removal and Installation Press the button once to search

for a parking space.

Press the button once to search

for a parking space.