Ford Fusion: Wheels and Tires / Wheels and Tires. Diagnosis and Testing

Preliminary Inspection

-

Verify the customer concern by carrying out a road test on a

smooth road. If any vibrations are apparent, Refer to the Symptom

Chart: NVH.

-

To maximize tire performance, inspect for signs of incorrect

inflation and uneven wear, which may indicate a need for balancing,

rotation or front suspension alignment.

-

Correct tire pressure and driving techniques have an

important influence on tire life. Heavy cornering, excessively rapid

acceleration and unnecessary sharp braking increase tire wear.

Replacement tires must follow the recommended:

- tire sizes.

- speed rating.

- load range.

- tire construction type.

The use of any other tire/wheel size, load range or type can seriously affect:

- ride.

- handling.

- speedometer/odometer calibration.

- vehicle ground clearance.

- tire clearance between the body and chassis.

- wheel bearing life.

- braking performance.

New wheels need to be installed when the vehicle wheels:

- are bent.

- are cracked.

- are dented.

- are heavily corroded.

- are leaking.

- have elongated wheel hub bolt holes.

- have excessive lateral or radial runout.

It is mandatory to use only the tire sizes recommended on the tire label located on the driver door or door pillar attached to the vehicle. Larger or smaller tires can damage the vehicle, affect durability and require changing the speedometer calibration. Make sure wheel size and offset match the original wheel specification for the tire in use.

Inspect the tires for signs of uneven wear. the following descriptions to identify the type of wear.

Check the tires for:

- cuts.

- stone bruises.

- abrasions.

- blisters.

- embedded objects.

Check the valve stems for:

- cracks.

- cuts.

Install a new valve stem when damage is found or anytime a new tire or wheel is installed.

Tread wear indicators are molded into the bottom of the tread grooves. Install a new tire when the indicator bands become less than measurement 1.6mm (2/32 inch).

Tire Wear

Tire wear is commonly defined as a loss of tread depth. Tire tread wear occurs due to friction with the contact surface (road/pavement). The tread should wear down uniformly all the way around the circumference of the tire and all the way across the tread face. When this does not occur, the tire may have abnormal/incorrect wear.

Normal Tire Wear

Normal tire wear is identified as even wear around and across the tread. Because there are many factors (driving style, road surfaces, type of vehicle, type of tire) that can affect tire wear, there is no absolute mileage expectation for a normal wear condition. A tire is considered worn-out when the tread has worn to the level of the tread-wear indicators.

Abnormal/Incorrect Tire Wear

Abnormal/incorrect tire wear is identified as tire wear that is not even around or across the tread and that creates performance-related issues.

Abnormal/incorrect wear can be caused by numerous factors, some of which include driving style (aggressive, passive), climate (hot, cold), road conditions, vehicle loading and maintenance (correct tire pressure, rotation intervals and balance). It is important to determine the root cause of wear on a vehicle before carrying out repair. Tires exhibiting abnormal/incorrect tire wear may still be serviceable provided that the minimum tread depth is greater than 1.6mm (2/32 inch) and the tire is not causing a vehicle performance (noise/vibration) concern.

Inner Edge/Shoulder Wear

Inner edge (or shoulder) wear occurs on the inside edge of the tire and is usually caused by excessive toe out and/or excessive negative camber. If the tread depth of the outer shoulder is at least 50% greater than the tread depth of the inner shoulder, the tire is experiencing inner edge/shoulder wear. To determine whether tires have this type of wear, visually inspect the tires. In some instances, it may be necessary to measure the tread depth of each rib and compare it to that of the shoulder.

NOTE: Right Front tire shown, others similar.

Outer Edge/Shoulder Wear

Outer edge (or shoulder) wear occurs on the outside edge of the tire and is usually caused by excessive toe in and/or excessive positive camber. If the tread depth of the inner shoulder is at least 50% greater than the tread depth of the outer shoulder, the tire is experiencing outer edge/shoulder wear. To determine whether tires have this type of wear, visually inspect the tires. In some instances, it may be necessary to measure the tread depth of each rib and compare it to that of the shoulder.

NOTE: Right Front tire shown, others similar.

Heel/Toe Wear

Heel/toe wear (also known as feathering) occurs along the outside or inside edge/shoulder of the tire. To determine whether tires have this type of wear, visually inspect the tires in both the inside and outside shoulder ribs. In some instances, it may be necessary to measure the difference in tread depth of leading versus trailing edge of each lug in the inside and outside shoulder rib.

Diagonal Wear

Diagonal wear occurs diagonally across the tread area and around the circumference of the tire. To determine whether tires have this type of wear, visually inspect the tires to determine if the wear pattern runs diagonally across the tread and around the circumference of the tire. In some instances, the difference in tread depth along the diagonal wear pattern may need to be measured.

Symptom Chart(s)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

WARNING:

Vehicle may have multiple drive wheels. Do not use engine to

power the driveline unless all drive wheels are elevated off the

ground. Drive wheels in contact with ground could cause unexpected

vehicle movement. Failure to follow this instruction may result in

serious personal injury.

WARNING:

Vehicle may have multiple drive wheels. Do not use engine to

power the driveline unless all drive wheels are elevated off the

ground. Drive wheels in contact with ground could cause unexpected

vehicle movement. Failure to follow this instruction may result in

serious personal injury.

Symptom Chart: Tire Wear

| Condition | Actions |

|---|---|

| Inner edge/shoulder wear | GO to Pinpoint Test A |

| Outer edge/shoulder wear | GO to Pinpoint Test B |

| Heel/toe wear | GO to Pinpoint Test C |

| Diagonal wear | GO to Pinpoint Test D |

Symptom Chart: NVH

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

NOTE: If equipped, the Lane Keeping System (LKS) can interfere with accurate NVH diagnostics. Disable the Lane Keeping System (LKS) before test driving the vehicle to diagnose NVH concerns. For information on disabling the Lane Keeping System (LKS), refer to the Owner's Literature.

NVH

symptoms should be identified using the diagnostic tools that are

available. For a list of these tools, an explanation of their uses and a

glossary of common terms,

REFER to: Noise, Vibration and Harshness (NVH) (100-04 Noise, Vibration and Harshness, Description and Operation).

Since it is possible any one of multiple systems may be the cause of a

symptom, it may be necessary to use a process of elimination type of

diagnostic approach to pinpoint the responsible system. If this is not

the causal system for the symptom, REFER to: Noise, Vibration and Harshness (NVH) (100-04 Noise, Vibration and Harshness, Description and Operation).

for the next likely system and continue diagnosis.

| Condition | Actions |

|---|---|

| Wobble or shimmy | GO to Pinpoint Test E |

| High-speed shake | GO to Pinpoint Test F |

| Vehicle vibration | GO to Pinpoint Test F |

Pinpoint Tests

PINPOINT TEST A : INNER EDGE, SHOULDER WEAR

PINPOINT TEST A : INNER EDGE, SHOULDER WEAR|

Normal Operation and Fault Conditions

REFER to: Safety Precautions - Overview (204-04A Wheels and Tires, Description and Operation). Possible Sources

|

||||

| A1 MEASURE THE TREAD DEPTH | ||||

Is the tread depth greater than 1.588 mm (0.0625 in) ?

|

PINPOINT TEST B : OUTER EDGE, SHOULDER WEAR

PINPOINT TEST B : OUTER EDGE, SHOULDER WEAR|

Normal Operation and Fault Conditions

REFER to: Safety Precautions - Overview (204-04A Wheels and Tires, Description and Operation). Possible Sources

|

||||

| B1 MEASURE THE TREAD DEPTH | ||||

Is the tread depth greater than 1.588 mm (0.0625 in) ?

|

PINPOINT TEST C : HEEL/TOE WEAR

PINPOINT TEST C : HEEL/TOE WEAR|

Normal Operation and Fault Conditions

REFER to: Safety Precautions - Overview (204-04A Wheels and Tires, Description and Operation). Possible Sources

|

||||

| C1 MEASURE THE TREAD DEPTH | ||||

Is the tread depth greater than 1.588 mm (0.0625 in) ?

|

PINPOINT TEST D : DIAGONAL WEAR

PINPOINT TEST D : DIAGONAL WEAR|

Normal Operation and Fault Conditions

REFER to: Safety Precautions - Overview (204-04A Wheels and Tires, Description and Operation). Possible Sources

|

||||

| D1 MEASURE THE TREAD DEPTH | ||||

Is the tread depth greater than 1.588 mm (0.0625 in) ?

|

PINPOINT TEST E : WOBBLE OR SHIMMY

PINPOINT TEST E : WOBBLE OR SHIMMY|

Normal Operation and Fault Conditions

REFER to: Safety Precautions - Overview (204-04A Wheels and Tires, Description and Operation). Possible Sources

|

||||

| E1 CHECK FOR LOOSE WHEEL NUTS | ||||

Are there any loose wheel nuts?

|

||||

| E2 BENT WHEEL / DAMAGED TIRE | ||||

Are any of the wheels bent or tires damaged ?

|

PINPOINT TEST F : HIGH SPEED SHAKE OR VEHICLE VIBRATION

PINPOINT TEST F : HIGH SPEED SHAKE OR VEHICLE VIBRATION|

Normal Operation and Fault Conditions

REFER to: Safety Precautions - Overview (204-04A Wheels and Tires, Description and Operation). Possible Sources

|

||||

| F1 BENT WHEEL / DAMAGED TIRE | ||||

Are any of the wheels bent or tires damaged ?

|

||||

| F2 CHECK RADIAL RUNOUT | ||||

Is radial runout correct?

|

Component Test- Radial Runout

Radial runout is the egg-shaped deviation from a perfect circle and is measured perpendicular to the circumference. On a wheel and tire assembly, this means measuring the center tire tread rib. The center rib is indicative of the condition of the tire as a whole. Total runout is the difference between the maximum-to-minimum gauge reading. The high spot is the location of maximum runout.

| Item | Description |

|---|---|

| 1 | High spot |

| 2 | Low spot |

Radial Runout Measurement - Loaded Hunter Road Force® Method

NOTE: Diagnosis of tire/wheel vibration should not be performed on tires with less than 322 km (200 mi). Some initial tire/wheel vibration issues (such as flat spotting) may correct themselves after the tires have been in service for 322 km (200 mi). This procedure will assist with the diagnosis of wheel and tire assembly runout and/or force variation issues. This procedure is intended to be used with a Hunter Road Force® balancer that measures the wheel and tire assembly's loaded runout and the tire's radial spring rate. The balancer then converts the runout into pounds of force (termed as Road Force). Measuring loaded runout (Road Force) is more effective than measuring unloaded runout using a dial indicator.

-

Using a tire crayon, record the vehicle position on the inward sidewall of all 4 tires.

-

Remove the wheel and tire assemblies.

REFER to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

-

NOTE: Use only a digital tire pressure gauge any time tire pressures are measured to be sure that accurate values are obtained.

Make sure that the tire pressures are set to the correct pressure as indicated on the tire pressure label.

-

NOTICE: Make sure that the correct wheel balancer adapters are used when mounting the assembly to the wheel balancer. This will prevent the possibility of inducing runout by using incorrect adapters and/or wheel damage.

NOTE: Modern balancers typically list the correct adapter when selecting the vehicle in the application menu. For additional instructions, refer the balancer’s user manual for proper adapter selection.

NOTE: Make sure that the wheel and tire assembly is clean and free of foreign material prior to installation on the balancer.

NOTE: The wheel balancer inflation station must be turned OFF for tires with inflation pressures of 60.0 psi ( 414 kPa) or above.

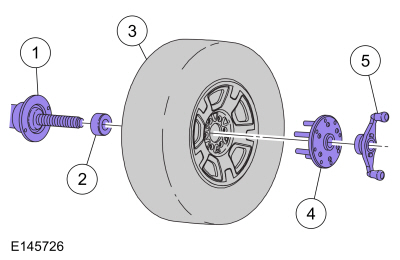

Mount the wheel and tire assembly on a suitable wheel balancer using the correct wheel balancer adapters as shown.

| Item | Description |

|---|---|

| 1 | Wheel balancer |

| 2 | Cone |

| 3 | Wheel and tire assembly |

| 4 | Finger plate |

| 5 | Balancer wing nut |

-

Measure the Road Force®.

- Temporarily mark the high spot and the Road Force® value on the sidewall of the tire. If the wheel and tire assembly Road Force® value is greater than 9 kg (20 lb), carry out the Match Mounting procedure to optimize the wheel and tire assembly.

- If the wheel and tire assembly Road Force® value is 9 kg (20 lb) or less, permanently mark the high spot and the Road Force® value on the inward sidewall of the tire for reference during future wheel and tire service. Balance the assembly and install the wheel and tire on the vehicle using the Wheel-to-Hub Optimization procedure.

Radial Runout Measurement - Dial Indicator Method

NOTE: Diagnosis of tire/wheel vibration should not be performed on tires with less than 322 km (200 mi). Some initial tire/wheel vibration issues (such as flat spotting) will correct themselves after the tires have been in service for 322 km (200 mi).

NOTE: Loaded run-out measurements are the preferred method for verifying tire serviceability. While a dial indicator can be used to optimize the position of the tire on the wheel, the unloaded run-out measurement cannot accurately determine if the tire should be removed from service.

NOTE: The following procedures should be used if normal diagnostics leads to a potential runout issue.

NOTE: Some vehicles may exhibit a wheel and tire vibration caused by excessive runout. Radial runout measurements can be taken using a dial indicator and should be measured with the wheel and tire assembly mounted on a suitable wheel balancer. The dial indicator should be mounted securely to eliminate gauge movement when measuring runout.

NOTE: Use only a digital tire pressure gauge any time tire pressures are measured to be sure that accurate values are obtained.

-

Make sure that the tire pressures are set to the correct pressure as indicated on the VC label.

-

Using a tire crayon, record the vehicle position on the inward sidewall of all 4 tires.

-

Remove the wheel and tire assemblies.

REFER to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

-

NOTICE: Make sure that the correct wheel balancer adapters are used when mounting the assembly to the wheel balancer or damage to the wheel may occur.

NOTE: Make sure that the wheel and tire assembly is clean and free of foreign material prior to installation on the balancer.

NOTE: The wheel balancer inflation station must be turned OFF for tires with inflation pressures of 60.0 psi ( 414 kPa) or above.

Mount the wheel and tire assembly on a suitable wheel balancer using the correct wheel balancer adapters as shown.

| Item | Description |

|---|---|

| 1 | Wheel balancer |

| 2 | Cone |

| 3 | Wheel and tire assembly |

| 4 | Finger plate |

| 5 | Balancer wing nut |

-

NOTE: Masking tape can be applied on the center tread rib to allow for a smoother measuring surface. Some fluctuation of the gauge reading is expected. Observe the overall sweep of the gauge from the highest to the lowest spot on the tire.

Position a suitable dial indicator and stand with the dial indicator on the center tread rib.

- Rotate the wheel and tire assembly (or wheel) to locate the low spot.

- Adjust the runout gauge to read 0.

- Rotate the wheel and tire assembly one complete revolution to make sure that the low spot has been found and that the dial indicator returns to a 0 reading.

-

While slowly and constantly rotating the wheel and tire assembly (or wheel), measure the radial runout.

- Note the variance (runout) from 0 on the dial of the gauge.

- If the runout reading of a wheel and tire assembly is greater than 1.14 mm (0.045 in), locate and temporarily mark the high spot and runout reading on the sidewall of the tire and carry out the Match Mounting procedure to optimize the wheel and tire assembly.

- If the runout reading of a wheel and tire assembly is 1.14 mm (0.045 in) or less, permanently mark the high spot and the runout reading on the inward sidewall of the tire for reference during future wheel and tire service. Balance the assembly and install the wheel and tire on the vehicle using the Wheel-to-Hub Optimization procedure.

Safety Precautions - Overview. Description and Operation

Safety Precautions - Overview. Description and Operation

Overview

Before beginning any service procedure in this manual, refer to health

and safety warnings in section 100-00 General Information. Failure to

follow this instruction may result in serious personal injury...

Wheel and Tire. Removal and Installation

Wheel and Tire. Removal and Installation

Materials

Name

Specification

Motorcraft® High Temperature Nickel Anti-Seize LubricantXL-2

-

Removal

With the vehicle in NEUTRAL, position it on a hoist...

Other information:

Ford Fusion 2013–2020 Owners Manual: Front Fog Lamps (IF EQUIPPED)

Switching the Front Fog Lamps On or Off Only switch the front fog lamps on during reduced visibility. You can switch the front fog lamps on if any of the following occur: You set the lighting control to the parking lamps position. You set the lighting control to the headlamps position...

Ford Fusion 2013–2020 Service Manual: Front Bumper Cover. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. Remove the front wheels and tires. Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation). On both sides. Remove the rivet push pin and the screws from the front of the fender liner...

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Body Control Module (BCM). Removal and Installation

- Transmission - 1.5L EcoBoost (118kW/160PS) – I4. Removal and Installation

- Steering Column Control Module (SCCM). Removal and Installation

- New on site

- Most important about car

Child Safety Locks

When these locks are set, the rear doors cannot be opened from the inside.

PINPOINT TEST A : INNER EDGE, SHOULDER WEAR

PINPOINT TEST A : INNER EDGE, SHOULDER WEAR