Ford Fusion: Engine - 1.5L EcoBoost (118kW/160PS) – I4 / Engine. Removal

Special Tool(s) /

General Equipment

|

300-OTC1585AE

Powertrain Lift |

|

300-OTC1819E

2,200# Floor Crane, Fold Away |

|

303-1502

Lifting Device Engine

TKIT-2012A-FL

TKIT-2012A-ROW |

|

307-569

Disconnect Tool TOC Line (1/2)

TKIT-2006U-F/FM

TKIT-2006U-FLM/LM

TKIT-2006U-ROW1

TKIT-2006U-ROW2 |

| Strap Wrench |

| Adjustable Mounting Arm |

| Oil Drain Equipment |

| Hose Clamp Remover/Installer |

| Wooden Block |

All vehicles

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

-

Release the fuel system pressure.

Refer to: Fuel System Pressure Release (310-00A Fuel System - General Information - 1.5L EcoBoost (118kW/160PS) – I4, General Procedures).

-

Keep the steering wheel in the straight-ahead position.

-

Remove and discard the bolt. Detach the steering column shaft from steering input shaft.

Torque:

18 lb.ft (25 Nm)

-

Remove the engine appearance cover.

-

Recover the A/C system.

Refer to: Air Conditioning (A/C) System Recovery, Evacuation and Charging - Vehicles With: R1234YF Refrigerant (412-00 Climate Control System - General Information, General Procedures).

-

Drain the cooling system.

Refer to: Engine Cooling System Draining, Vacuum Filling and Bleeding (303-03A Engine Cooling - 1.5L EcoBoost (118kW/160PS) – I4, General Procedures).

-

Remove the following items:

-

Remove the air cleaner.

Refer to: Air Cleaner (303-12A Intake Air Distribution and Filtering - 1.5L EcoBoost (118kW/160PS) – I4, Removal and Installation).

-

Remove the upper air cleaner outlet pipe.

Refer to: Air Cleaner Outlet Pipe (303-12A Intake Air Distribution and Filtering - 1.5L EcoBoost (118kW/160PS) – I4, Removal and Installation).

-

Remove the battery tray.

Refer to: Battery Tray (414-01 Battery, Mounting and Cables, Removal and Installation).

-

NOTE:

Always wrap the fuel line connection with a towel before disconnecting it.

Detach the retainers, disconnect the couplings and position the fuel tube aside.

-

Detach the retainer and disconnect the coupling and position the vacuum tube aside.

-

Disconnect the crankcase pressure sensor wiring harness electrical connector and wire harness retainer.

-

Remove the EVAP canister purge valve.

Refer to: Evaporative Emission Canister Purge Valve (303-13A Evaporative Emissions - 1.5L EcoBoost (118kW/160PS) – I4, Removal and Installation).

-

Remove the stud bolt and position the wiring harness aside.

-

Release the tabs and position the fuse box aside.

-

Release the tabs and open the battery cable terminal cover.

-

Remove the nuts and position the wiring harness aside.

-

Detach the retainers, remove the bolts and position the wiring harness aside.

-

Disconnect the coolant hose.

Use the General Equipment: Hose Clamp Remover/Installer

-

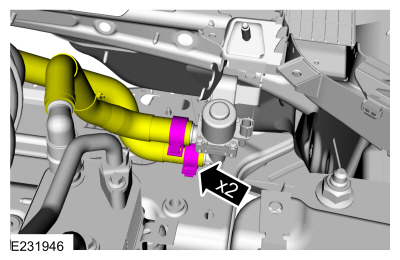

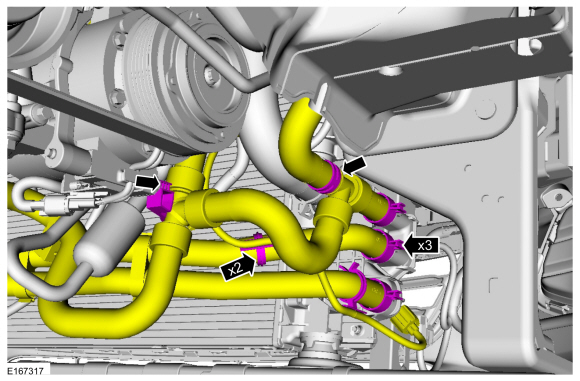

Remove the transmission fluid cooler tubes secondary latches.

-

Using the special tool, disconnect the transmission fluid cooler tubes.

Use Special Service Tool: 307-569

Disconnect Tool TOC Line (1/2).

-

Detach the retainer and disconnect the coolant tube.

Use the General Equipment: Hose Clamp Remover/Installer

-

NOTE:

If equipped with block heater.

Detach the retainers and disconnect the coolant tube.

-

Remove the bolts and disconnect the gearshift cable end from selector lever assembly.

-

NOTE:

Note the position of the coolant hoses for installation.

Disconnect the coolant hoses from the heater core.

Use the General Equipment: Hose Clamp Remover/Installer

-

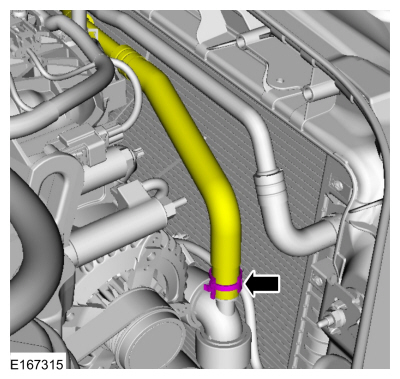

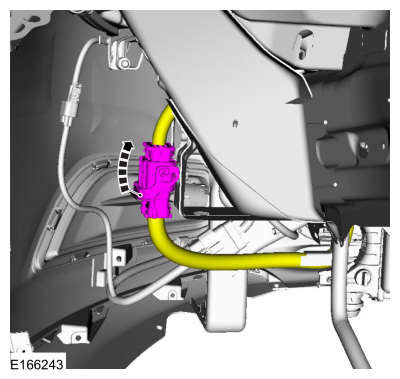

Release the clamps and disconnect the coolant hoses from the transmission fluid heater coolant control valve.

Use the General Equipment: Hose Clamp Remover/Installer

-

Disconnect the coolant hose.

Use the General Equipment: Hose Clamp Remover/Installer

-

Disconnect the PCM electrical connector.

-

Detach the wiring harness retainer, disconnect the electrical connector and position the wiring harness aside.

-

-

Disconnect the coolant hoses.

Use the General Equipment: Hose Clamp Remover/Installer

-

Release the tab, remove the retainer and the degas bottle.

-

Support the cooling module.

-

Remove the accessory drive belt.

Refer to: Accessory Drive Belt (303-05A Accessory Drive - 1.5L EcoBoost (118kW/160PS) – I4, Removal and Installation).

-

Remove the RH and LH front wheels and tires.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

-

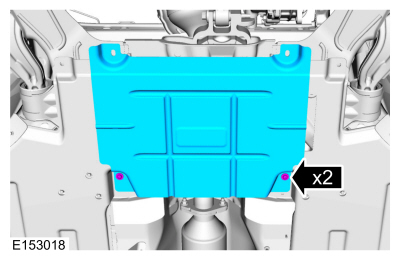

Remove the retainers and the stone guard.

-

Remove the retainers and the deflector shields.

-

NOTE:

LH inner fender well removed for clarity.

Disconnect the electrical connector.

-

Remove the retainers and the lower radiator support.

-

Disconnect the coolant hoses and detach the retainers.

Use the General Equipment: Hose Clamp Remover/Installer

-

Disconnect the coolant hose.

Use the General Equipment: Hose Clamp Remover/Installer

-

Disconnect the electrical connectors, detach the retainers and position wiring harness aside.

-

NOTE:

Discard the O-ring seals and gasket seals.

Remove the nuts and position the A/C lines aside.

-

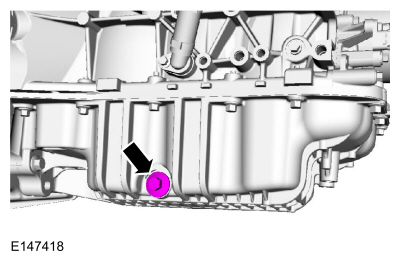

Remove the drain plug, drain engine oil and install drain plug.

Use the General Equipment: Oil Drain Equipment

Torque:

21 lb.ft (28 Nm)

-

Remove and discard the engine oil filter.

Use the General Equipment: Strap Wrench

-

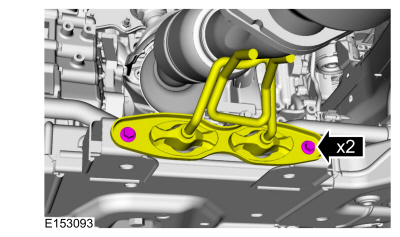

Remove the bolts and the cross support.

-

Remove the nuts and position the muffler inlet pipe aside. Discard the nuts.

-

Remove and discard the muffler inlet pipe gasket.

-

Mark on subframe before removal.

-

Mark on subframe before removal.

-

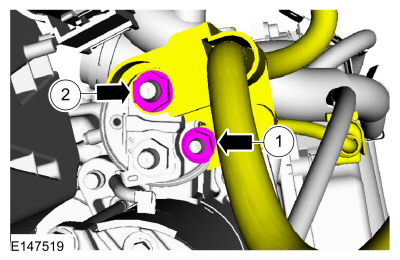

Remove the bolts and position the auxiliary water pump aside.

-

NOTE:

One of these bolts will be used to mount the Adjustable Mounting Arm to the powertrain.

Remove the engine to transmission bolts.

-

Remove the nuts and the catalytic converter grommet.

-

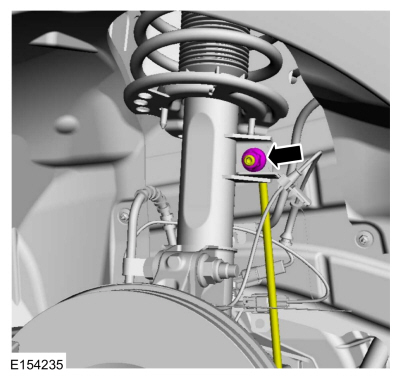

Remove the bolt position the wheel speed sensor aside.

-

Remove the bolt position the wheel speed sensor aside.

-

Remove the nut and position the LH stabilizer bar link aside.

-

Remove the nut and position the RH stabilizer bar link aside.

-

Position a 2 x 8 board, 40 in (1016 mm) in length, a 2 x

6 board 28 in (711.2 mm) in length, a 1 x 6 board 28 in (711.2 mm) in

length and two 2 x 4 boards 12 in (304.8 mm) in length onto the

Powertrain Lift 300-OTC1585AE.

Install Special Service Tool: 300-OTC1585AE

Powertrain Lift.

Use the General Equipment: Wooden Block

-

Install Special Service Tool: 300-OTC1585AE

Powertrain Lift.

Use the General Equipment: Wooden Block

-

Install the adjustable mounting arm.

Use the General Equipment: Adjustable Mounting Arm

-

Remove the brake disc.

Refer to: Brake Disc (206-03 Front Disc Brake, Removal and Installation).

-

Remove the nuts, bolts and the position the LH wheel knuckle assembly aside.

-

Remove the nuts, bolts and the position the RH wheel knuckle assembly aside.

-

Remove the transmission support insulator nut.

-

-

Remove the nuts, bolts and the engine mount.

-

Discard the nuts and bolts.

-

-

Remove and discard the subframe rear mounting bolts.

-

Remove the bolts and the subframe support bracket.

-

Remove and discard the subframe front mounting bolts.

-

Using the powertrain lift, lower the powertrain and subframe as an assembly.

-

Detach the retainer and disconnect the electrical connectors.

-

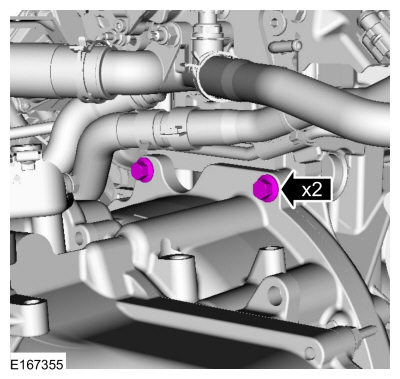

Remove the muffler inlet pipe isolator bracket bolts.

-

Remove and discard the catalytic converter bolt.

-

Remove the bolts and the catalytic converter. Discard the bolts.

-

Remove and discard the catalytic converter gasket.

-

Detach the wiring harness retainers and disconnect the electrical connectors.

Vehicles with automatic start-stop

-

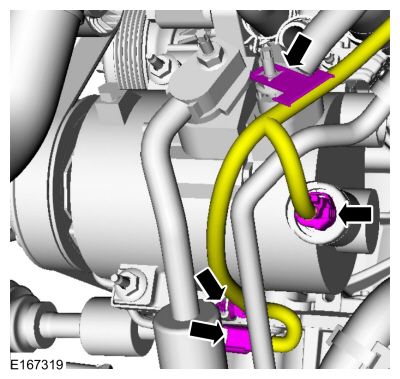

Disconnect the coolant hoses.

Use the General Equipment: Hose Clamp Remover/Installer

All vehicles

-

Remove the nuts and position the starter motor cable aside.

-

-

Detach the wiring harness retainers, disconnect the electrical connector.

-

Slide the generator insulator up, remove the nut and position the wiring harness aside.

-

Remove the nut and position the wiring harness aside.

-

Remove the bolts, stud bolt and the starter motor.

-

Remove the starter motor insulator.

-

NOTE:

Only rotate the crankshaft in a clockwise direction.

Index-mark the torque converter nuts. Remove and discard the torque converter nuts.

-

-

Detach the wiring harness retainer.

-

Disconnect and remove the crankcase vent hose.

Use the General Equipment: Hose Clamp Remover/Installer

-

-

Detach the wiring harness retainers and disconnect the electrical connectors.

-

Disconnect the TC bypass hose.

-

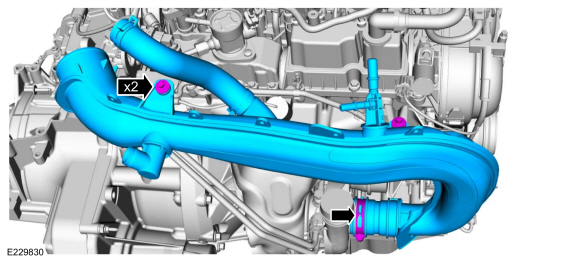

Loosen the clamp, remove the bolt and the TC outlet pipe.

-

Loosen the clamp, remove the bolts and the TC inlet pipe.

-

Remove the bolts and position the halfshaft support bracket aside.

-

Remove the bolts and the bracket.

-

Install Special Service Tool: 303-1502

Lifting Device Engine.

-

Install Special Service Tool: 300-OTC1819E

2,200# Floor Crane, Fold Away.

-

Remove the bolts and the adjustable mounting arm.

Use the General Equipment: Adjustable Mounting Arm

-

Remove the engine to transmission bolts.

-

Remove the engine to transmission bolts.

-

Remove the bolt and separate the engine from transmission.

Special Tool(s) /

General Equipment

100-001

(T50T-100-A)

Slide Hammer

300-OTC1819E2,200# Floor Crane, Fold Away

303-1097Locking Tool, Variable Camshaft Timing Oil Control UnitTKIT-2010B-FLMTKIT-2010B-ROW

303-1502Lifting Device EngineTKIT-2012A-FLTKIT-2012A-ROW

303-409

(T92C-6700-CH)

Remover, Crankshaft SealTKIT-1992-FH/FMH/FLMHTKIT-1993-LMH/MH

303-748L..

Other information:

Removal

NOTE:

Removal steps in this procedure may contain installation details.

NOTICE:

Do not service the brake pedal or brake booster

without first removing the stoplamp switch. This switch must be removed

with the brake pedal in the at-rest position. The switch plunger must be

compressed for the switch to rotate in the bracket. Attempting to

remove the switch when the plunger ..

Removal

NOTE:

Removal steps in this procedure may contain installation details.

NOTE:

RH seat shown, LH seat similar.

Remove the screw.

Torque:

8 lb.in (0.9 Nm)

Disconnect the electrical connector.

Remove the seat position sensor.

Installation

To install, reverse the removal procedure.

..

Engine. Disassembly

Engine. Disassembly